D

Dennis Sorensen

Guest

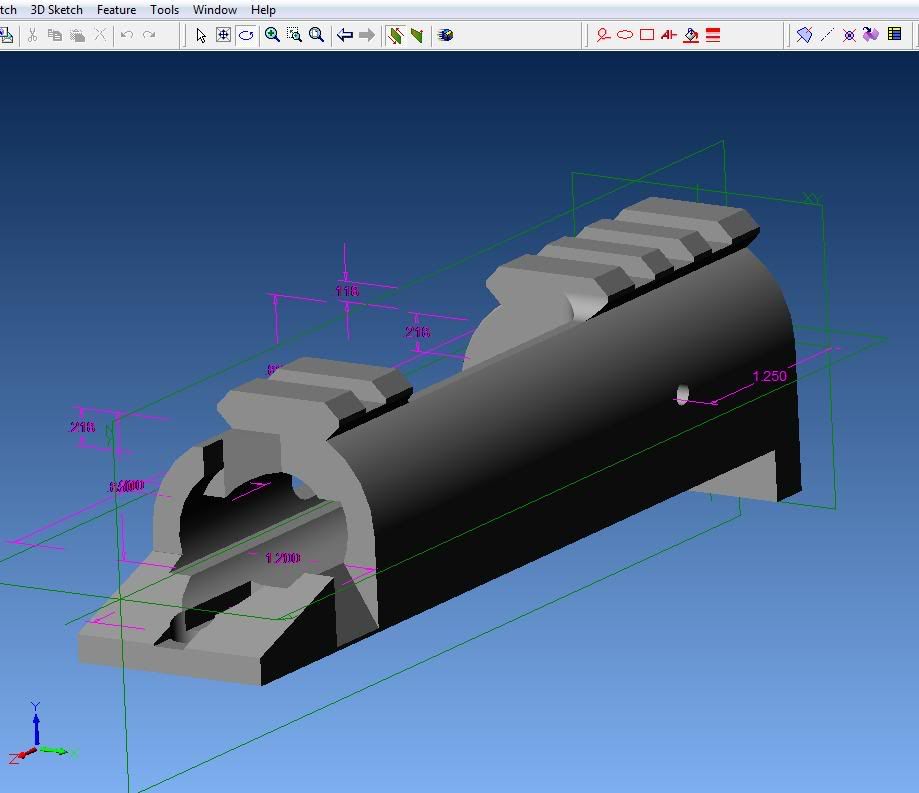

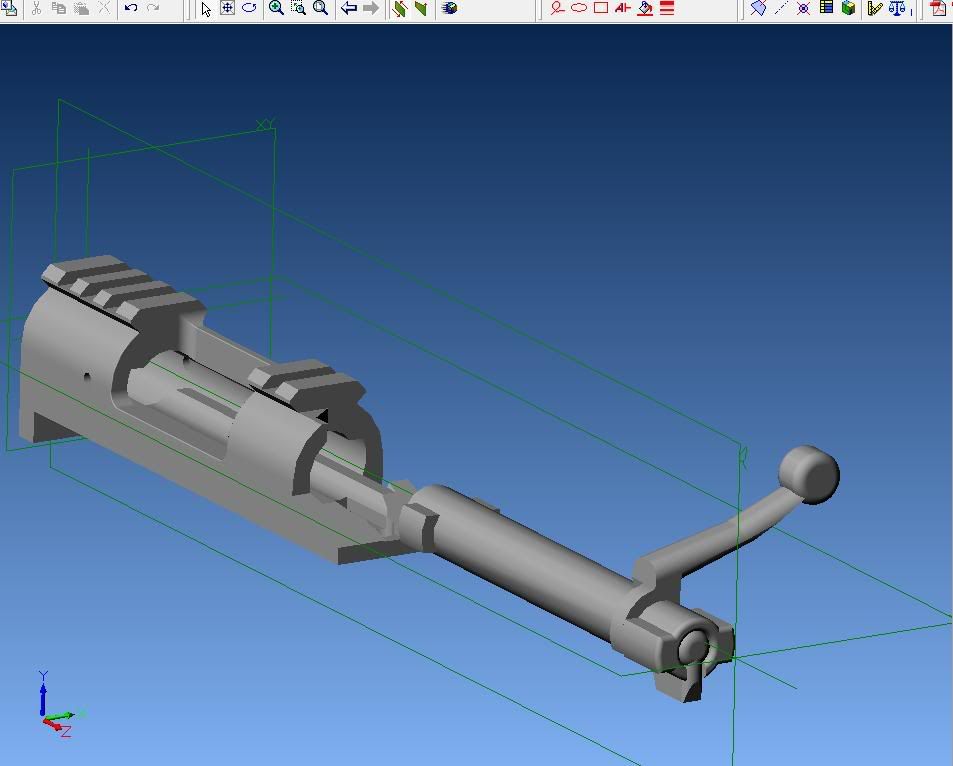

Here is one that is 1/2" shorter than a model 7, has an integral recoil lug, uses 2 remington front bases and remington pattern triggers. It also has a cone breech and a Sako extractor no ejector. Brad Stair at 801-731-8152 makes these.

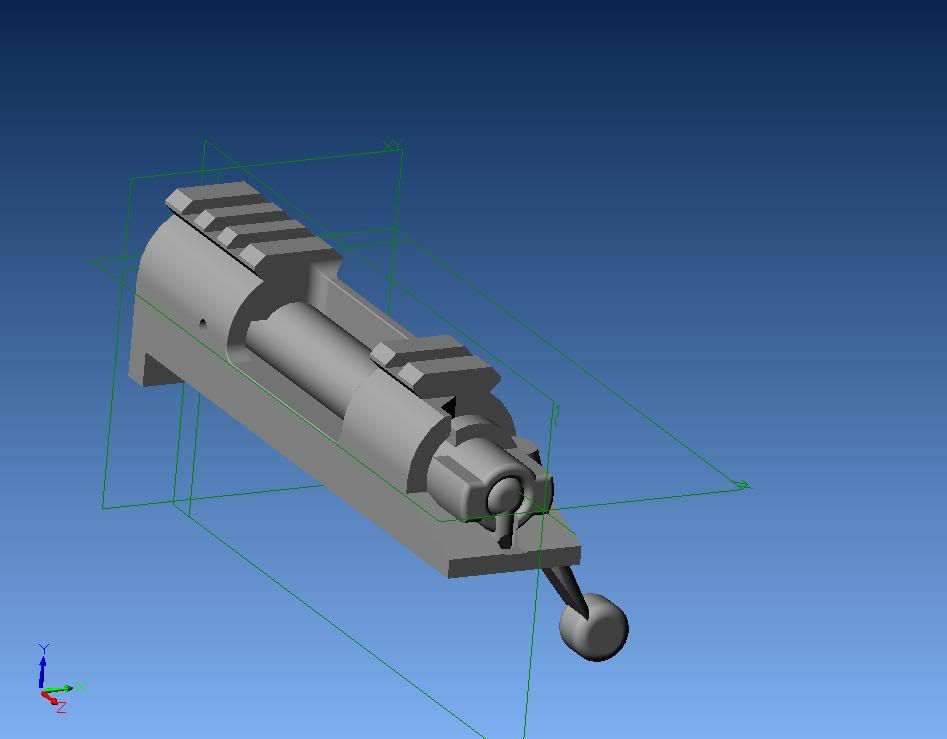

If the photos are correct it is interesting that when the bolt is closed the extractor is "buried" on the solid side of the action... considerable safer that way... but it would not work with an ejector...