jackie schmidt

New member

Today, a good friend had a 22PPC Short at the range, with 2 new 1-14 twist barrel.

To his amazement, very few of the bullets were reaching the target, vaporizing on the trip down.

He spent the better part of the day trying to figure out what was up. He put it through my Chronograph, and he was only shooting a tad over 3400.

He put on the second barrel, and it did not have any problems. I finally looked down the bore of the suspect barrel, and I could tell that it was WAY faster than a 1-14. It turns out, by checking it with a cleaning rod, it is either a 6 or 7 twist.

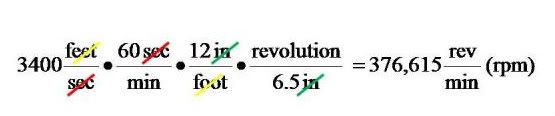

My question is, what RPM were those bullets spinning. Take 3400 fps at a 1-6.5 twist.

Another question. Since this was supposed to be a 1-14, and either got stamped wrong, or what ever, should the manufacturer be liable for all of the subsequent work ,ie, chambering and fitting it to the Rifle, as well as a new blank.

I have run into this in my business. We have put quite a few dollars in a piece of material that was on later inspection found to be flawed, and all the material supplyer would opt for is a new piece of steel. We had to eat the rest.........jackie

To his amazement, very few of the bullets were reaching the target, vaporizing on the trip down.

He spent the better part of the day trying to figure out what was up. He put it through my Chronograph, and he was only shooting a tad over 3400.

He put on the second barrel, and it did not have any problems. I finally looked down the bore of the suspect barrel, and I could tell that it was WAY faster than a 1-14. It turns out, by checking it with a cleaning rod, it is either a 6 or 7 twist.

My question is, what RPM were those bullets spinning. Take 3400 fps at a 1-6.5 twist.

Another question. Since this was supposed to be a 1-14, and either got stamped wrong, or what ever, should the manufacturer be liable for all of the subsequent work ,ie, chambering and fitting it to the Rifle, as well as a new blank.

I have run into this in my business. We have put quite a few dollars in a piece of material that was on later inspection found to be flawed, and all the material supplyer would opt for is a new piece of steel. We had to eat the rest.........jackie

Last edited: