F

frwillia

Guest

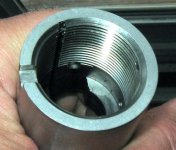

I used a Manson Mandrel to align them and machined the receiver faces on my Model 10 sporter and Model 12 Target action to be in orthogonal to the bolt axis. I was amazed at how far off they were.

The sporter needed .004" of material removed before it cleaned up, the Target action was worse, it needed .006" of material removed to clean up. In both cases the starting face finish looked like it had been done on a belt sander or something. The first cut, just in contact to get a reference, started with about 1/8 of the circumfrance cleaning up, it progressed pretty uniformly around the the outside suggesting the face was in fact tilted and not too flat.

I'll be interested to see if this, and increased torque, improves how they shoot.

Fitch

The sporter needed .004" of material removed before it cleaned up, the Target action was worse, it needed .006" of material removed to clean up. In both cases the starting face finish looked like it had been done on a belt sander or something. The first cut, just in contact to get a reference, started with about 1/8 of the circumfrance cleaning up, it progressed pretty uniformly around the the outside suggesting the face was in fact tilted and not too flat.

I'll be interested to see if this, and increased torque, improves how they shoot.

Fitch