Should rimfire benchrest shooters take a look at "Micro-Groove" match barrels........

Last year I decided to build a 10/22 benchrest rifle so I contacted a well known precision 10/22 action maker and didn’t hear back from him so I contacted another one. Both of these companies advertised with me when I published “Small Caliber News” and I liked their precision products. Finally the first one responded and I placed an order and wouldn’t you know it a little later the second company responded as well so I couldn’t say no to either one and I ended up building two rimfire benchrest rifles!

The first is an true benchrest build that is still ongoing (those stock makers take forever...lol..) but this second one I decided to just kind of put it together myself. So let’s take a look at the one I just finished up putting together with various components.

The action is a precision CST and their match bolt assembly. Then I added a Kidd 3 ounce trigger. For the stock I noticed a guy offering a handsome thumb hole Hickory all finished up on one of the forums. I was surprised nobody bought it as it was very reasonable. So after a month of it reappearing I decided to help him out and buy it! It’s not a true three inch bench stock with the forend at 2 1/4” inch and I’m fully aware of the thumb hole not necessarily conducive to the best handling but I used one many years ago in centerfire benchrest with decent results. I did install my own front and rear pillars and final bedding of the stock.

So I was down to selecting a match barrel. I looked at every one I could think of and actually contacted one of the top makers with what I thought was a poor response and would not have any available until late fall. Then out of curiosity I checked on EBay for maybe a decent used barrel. What I found was a company offering “Micro-Groove” barrels for the 10/22 by the name of Keystone Sporting Arms. That immediately peaked my interest as I remember as a very young guy starting my accuracy journey with a Marlin Sako in 222 Remington with a micro-groove barrel and did it shoot!

So after a little research I decided to order one of their Ruger 10/22 Blued ( to match the CST action) .920 Bull Precision Target 20” barrels all for $129.94! I felt at that price it was worth a try and at least I could finally get a custom match 10/22 going.

It arrived priority mail in three days and I was immediately impressed with the bluing and crown. I ran an oiled patch through then a dry one so I could do a quick bore scope. I can tell you those fine “Micro-grooves” look really cool! As always with any new barrel I took it to to my shop for a very good polish lap. After cleaning I finally installed it on my custom CST action.

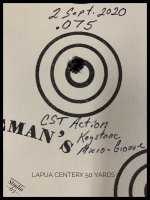

Finally it was time to go to my range. I set the rifle up and put up a target on my 50 yard bullet trap. My first five shot group was .527 the second group .373 the third a .107! I was tickled for sure. Now I was really starting to think about the possible advantage of the Micro-Groove barrel and the soft lead 22 bullets. Then last evening after getting out of work late I quickly went back up to my range but this time with a brand new lot of Lapua CenterX that had just arrived. This lot had recently proven very accurate in the Lapua test facility with my new Stiller 2500 and Shilen Rachet barrel.

As I fired my first three shots all were in one hole! The wind flags were lightly dancing around but continued to make no sense and it was getting dark. I decided to just shoot the remaining two rounds. At the final shot I was so relieved they all went in a ragged hole! Back down to my office with Ole Hickory ....that’s what I named it and the target. I measured it and was very pleased with a .075!

That got me to thinking all evening are we all missing something here with the old “Micro-Groove” barrel technology? Think of the possible advantages with the shallow lands and grooves with less deformation of the soft lead bullet. We know the Shilen Ratchet rifling advantages with less lead and fouling build up. Well the old Micro-Groove” technology offers something similar with their “tangentially disposed” (beveled to prevent accumulation of fouling) which enhances accuracy, ease of cleaning and elimination of gas leakage! Here is an article I found and I guess as they say there is nothing new under the sun!

“In 1953 Marlin applied for a patent on Microgroove rifling (US Patent #3,100,358 was granted on Aug. 13, 1953). In this patent, Microgroove rifling was described as having 5 grooves for every 1/10th of an inch bore diameter, and that the driving side of each land would be "tangentially disposed" (i.e. beveled, presumably to prevent the accumulation of fouling). On July 29, 1953, Marlin introduced Microgroove rifling in their .22 rimfire barrels, with 16 grooves that were .014" wide, and nominally .0015" deep. In their 1954 catalog, they outlined numerous advantages that this new form of rifling had, including better accuracy, ease of cleaning, elimination of gas leakage, higher velocities and lower chamber pressures. They also mentioned "...a bore of greater than standard size..." in their discussion of how Microgroove rifling did not engrave (distort) a bullet jacket as deeply as conventional rifling.”

By Glen Fryxell

So my question to all the rimfire experts is....should we take a hard look at Micro-Groove match barrels.

Sincerely,

Todd A. Kindler ( High Noon)

The Woodchuck Den Inc. & Founder Editor of Small Caliber News

Last year I decided to build a 10/22 benchrest rifle so I contacted a well known precision 10/22 action maker and didn’t hear back from him so I contacted another one. Both of these companies advertised with me when I published “Small Caliber News” and I liked their precision products. Finally the first one responded and I placed an order and wouldn’t you know it a little later the second company responded as well so I couldn’t say no to either one and I ended up building two rimfire benchrest rifles!

The first is an true benchrest build that is still ongoing (those stock makers take forever...lol..) but this second one I decided to just kind of put it together myself. So let’s take a look at the one I just finished up putting together with various components.

The action is a precision CST and their match bolt assembly. Then I added a Kidd 3 ounce trigger. For the stock I noticed a guy offering a handsome thumb hole Hickory all finished up on one of the forums. I was surprised nobody bought it as it was very reasonable. So after a month of it reappearing I decided to help him out and buy it! It’s not a true three inch bench stock with the forend at 2 1/4” inch and I’m fully aware of the thumb hole not necessarily conducive to the best handling but I used one many years ago in centerfire benchrest with decent results. I did install my own front and rear pillars and final bedding of the stock.

So I was down to selecting a match barrel. I looked at every one I could think of and actually contacted one of the top makers with what I thought was a poor response and would not have any available until late fall. Then out of curiosity I checked on EBay for maybe a decent used barrel. What I found was a company offering “Micro-Groove” barrels for the 10/22 by the name of Keystone Sporting Arms. That immediately peaked my interest as I remember as a very young guy starting my accuracy journey with a Marlin Sako in 222 Remington with a micro-groove barrel and did it shoot!

So after a little research I decided to order one of their Ruger 10/22 Blued ( to match the CST action) .920 Bull Precision Target 20” barrels all for $129.94! I felt at that price it was worth a try and at least I could finally get a custom match 10/22 going.

It arrived priority mail in three days and I was immediately impressed with the bluing and crown. I ran an oiled patch through then a dry one so I could do a quick bore scope. I can tell you those fine “Micro-grooves” look really cool! As always with any new barrel I took it to to my shop for a very good polish lap. After cleaning I finally installed it on my custom CST action.

Finally it was time to go to my range. I set the rifle up and put up a target on my 50 yard bullet trap. My first five shot group was .527 the second group .373 the third a .107! I was tickled for sure. Now I was really starting to think about the possible advantage of the Micro-Groove barrel and the soft lead 22 bullets. Then last evening after getting out of work late I quickly went back up to my range but this time with a brand new lot of Lapua CenterX that had just arrived. This lot had recently proven very accurate in the Lapua test facility with my new Stiller 2500 and Shilen Rachet barrel.

As I fired my first three shots all were in one hole! The wind flags were lightly dancing around but continued to make no sense and it was getting dark. I decided to just shoot the remaining two rounds. At the final shot I was so relieved they all went in a ragged hole! Back down to my office with Ole Hickory ....that’s what I named it and the target. I measured it and was very pleased with a .075!

That got me to thinking all evening are we all missing something here with the old “Micro-Groove” barrel technology? Think of the possible advantages with the shallow lands and grooves with less deformation of the soft lead bullet. We know the Shilen Ratchet rifling advantages with less lead and fouling build up. Well the old Micro-Groove” technology offers something similar with their “tangentially disposed” (beveled to prevent accumulation of fouling) which enhances accuracy, ease of cleaning and elimination of gas leakage! Here is an article I found and I guess as they say there is nothing new under the sun!

“In 1953 Marlin applied for a patent on Microgroove rifling (US Patent #3,100,358 was granted on Aug. 13, 1953). In this patent, Microgroove rifling was described as having 5 grooves for every 1/10th of an inch bore diameter, and that the driving side of each land would be "tangentially disposed" (i.e. beveled, presumably to prevent the accumulation of fouling). On July 29, 1953, Marlin introduced Microgroove rifling in their .22 rimfire barrels, with 16 grooves that were .014" wide, and nominally .0015" deep. In their 1954 catalog, they outlined numerous advantages that this new form of rifling had, including better accuracy, ease of cleaning, elimination of gas leakage, higher velocities and lower chamber pressures. They also mentioned "...a bore of greater than standard size..." in their discussion of how Microgroove rifling did not engrave (distort) a bullet jacket as deeply as conventional rifling.”

By Glen Fryxell

So my question to all the rimfire experts is....should we take a hard look at Micro-Groove match barrels.

Sincerely,

Todd A. Kindler ( High Noon)

The Woodchuck Den Inc. & Founder Editor of Small Caliber News