R

RJ MAX

Guest

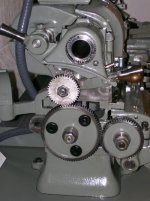

Due to helping pay some major medical bills for a family member, I find myself selling my Hy 10 with tooling if anyone is interested. I purchased the lathe about two years ago to do some rebarrel work (mainly for myself) and have done so along with making parts for my brothers transmisson and mud bogging jeep projects.

Since purchase I have stripped and painted the lathe, installed all new bearings and oil wicks thourghout while lathe was apart, new Dayton 3ph motor (original still works fine), rewired with liguid tight, installed VFD, changed leather belt to serpetine, installed needle bearings in cross slide and compound dials for smoother operation, new bronze nuts in compound and cross slide screws, and changed apron ball oilers to cup oilers (suggested on southbend forum for better way oiling). Tail stock was reconditioned by oversize boring the barrel bore, turning barrel to uniform diameter, setting up and aligning with headstock for Moglice injection. this tailstock improvement elimated play and as a test I set back and chambered an old take off barrel by pushing reamer with dead center in tail stock with a 0.0005 runout. I typically use a floating cup type holder I made with information from others on the forum, but as a test to the tail stock improvement I drove reamer direct from tail stock to see how well it all aligned.

Lathe Information: Catalog No. CLC 187A

bed length: 4 foot

SN: 11776-RKX-16

Spindle: D1-4

Motor: 1hp, 3ph

Tooling: steady rest (after market), original 6" 3 jaw with two set of jaws, import 8" indepent 4 jaw (I modified this chuck in order to use a receiver trunign jig purchased from Greg T.), collets 1/16" to 1"(by 1/16"), hand collet closer and spindle collet sleeve, spindle reducing sleeve (5MT to 3MT), 3MT dead center, tail stock (2MT) 2 dead and 1 live center, original latern tool post with holder and knurling tool, Phase II AXA tool post with holders, cat head for spindle outboard end, three oiling cans for lubricants, and remaining quanity of lathe lubricating oils.

Lathe will cut test bars: a chucked up piece of 1inch bar lathe will cut 0.0005 in 5 inch length, a 10 inch bar stock between centers is 0.0005- (this after tail stock Moglice injection).

I am asking $2,800.00 for lathe and tooling or please make offer. My direct email is ram16@comcast.net if interested. a few photos attached. additional photos via email if you wish.

Since purchase I have stripped and painted the lathe, installed all new bearings and oil wicks thourghout while lathe was apart, new Dayton 3ph motor (original still works fine), rewired with liguid tight, installed VFD, changed leather belt to serpetine, installed needle bearings in cross slide and compound dials for smoother operation, new bronze nuts in compound and cross slide screws, and changed apron ball oilers to cup oilers (suggested on southbend forum for better way oiling). Tail stock was reconditioned by oversize boring the barrel bore, turning barrel to uniform diameter, setting up and aligning with headstock for Moglice injection. this tailstock improvement elimated play and as a test I set back and chambered an old take off barrel by pushing reamer with dead center in tail stock with a 0.0005 runout. I typically use a floating cup type holder I made with information from others on the forum, but as a test to the tail stock improvement I drove reamer direct from tail stock to see how well it all aligned.

Lathe Information: Catalog No. CLC 187A

bed length: 4 foot

SN: 11776-RKX-16

Spindle: D1-4

Motor: 1hp, 3ph

Tooling: steady rest (after market), original 6" 3 jaw with two set of jaws, import 8" indepent 4 jaw (I modified this chuck in order to use a receiver trunign jig purchased from Greg T.), collets 1/16" to 1"(by 1/16"), hand collet closer and spindle collet sleeve, spindle reducing sleeve (5MT to 3MT), 3MT dead center, tail stock (2MT) 2 dead and 1 live center, original latern tool post with holder and knurling tool, Phase II AXA tool post with holders, cat head for spindle outboard end, three oiling cans for lubricants, and remaining quanity of lathe lubricating oils.

Lathe will cut test bars: a chucked up piece of 1inch bar lathe will cut 0.0005 in 5 inch length, a 10 inch bar stock between centers is 0.0005- (this after tail stock Moglice injection).

I am asking $2,800.00 for lathe and tooling or please make offer. My direct email is ram16@comcast.net if interested. a few photos attached. additional photos via email if you wish.