B

Bnhpr

Guest

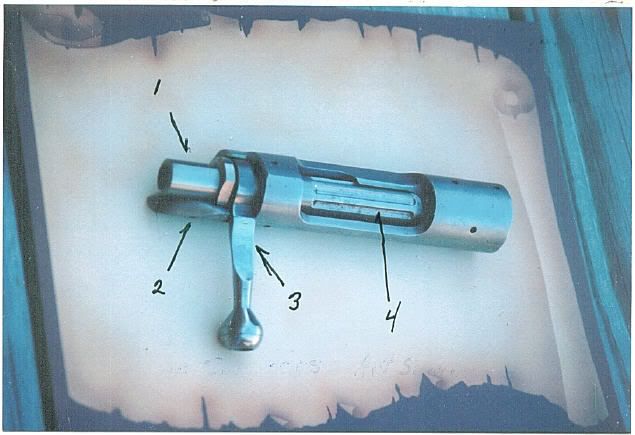

What's the norm for putting a custom knob on a 700 bolt?

I was planning on it being longer, for decreased lift force, and was going to turn an aluminum knob in the lathe.

I was thinking about machining the exixting knob off in the mill, so it left a square end, basically a continuation of the area below the existing knob.

Then, tap the end of it out to 1/4 28 or something, and either put a stud in it, or thru drill my new knob (i have not made yet) for a socket head cap screw.

Any advice appreciated.

Ben

I was planning on it being longer, for decreased lift force, and was going to turn an aluminum knob in the lathe.

I was thinking about machining the exixting knob off in the mill, so it left a square end, basically a continuation of the area below the existing knob.

Then, tap the end of it out to 1/4 28 or something, and either put a stud in it, or thru drill my new knob (i have not made yet) for a socket head cap screw.

Any advice appreciated.

Ben