G

Gator

Guest

I am posting this in the Gunsmithing Section due to it possibly having to do with an equipment problem. I did a search to see if I could find a simular problem but couldn't find that any had.

So, has this happened to anyone else in this manner (see pics).

I am open to suggestions as I am stumped as to why this happened.

Rifle history and description – I don’t think that it is an equipment problem as of yet but you guys might see or have experience that will mean otherwise:

Surgeon Action, Bedded into McMillian A-5 – Chambered in 6.5x284 (Tight Neck) – Lapua Brass (turned .001 under Chamber Dim.) – 142 Moly Coated Sierra HPBTMK – Seated At the Lands – 53.0 Gr. H4831SC – Jewell trigger – 27” 1:8 Bartlein Barrel – Nightforce 8x32

I installed this barrel about a year ago and it has shot excellent until recently but has started shooting better last couple of outings. I was shooting Federal 215M primers but didn’t want my supply to get too low so I tried the Remington 9 ½ primers since I had read some good things about them. I had aquired about seven hundred Remington 9 ½’s about 10 years ago and thought since everyone’s primer supply hasn’t been too reliable lately, I would see if I could use some them in the 6.5x284.

Well, I loaded up ten rounds with the normal Federal 215M primers, powder & bullet that I have always used plus ten rounds with the Remington primers and went to the range. Shot the first five at 1000 yds. with no problems other than they hit about 14” higher than normal and then the primer blew on the sixth. Looked everything over and didn’t see any abnormal pressure signs or a reason for the malfunction. Shot another – no problems. Shot the eighth round and another primer blew, so I said that’s enough of that.

I’m glad I had my safety glasses on. I shot five with the Federal primers and they all shot very well with no problems so I loaded up and headed home – about a five mile drive.

I didn’t think anything bad had gone wrong until I pulled the bolt to give it a good inspection and could see the damage done by the primers. So I got my microscope out and looked at all of the rounds that had the Remington primers and the Federal primers.

This is what I found. I will post remaining pics in the following post.

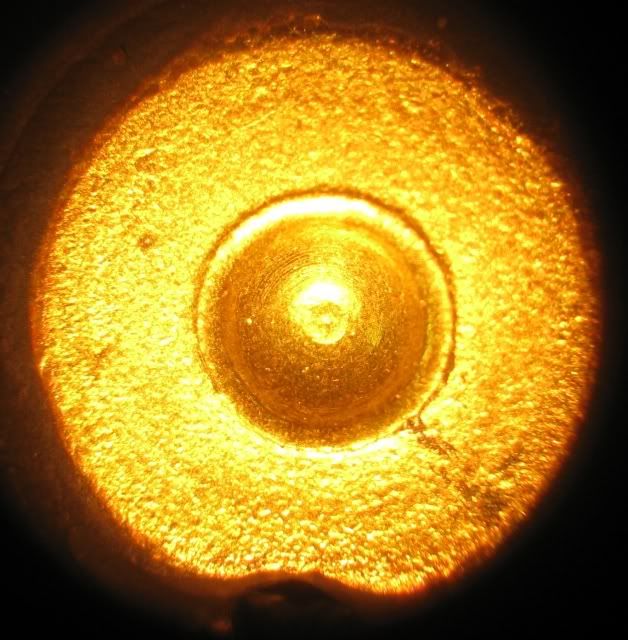

Case head - Sorry, I didn't take a pic of the other one but it looked the same.

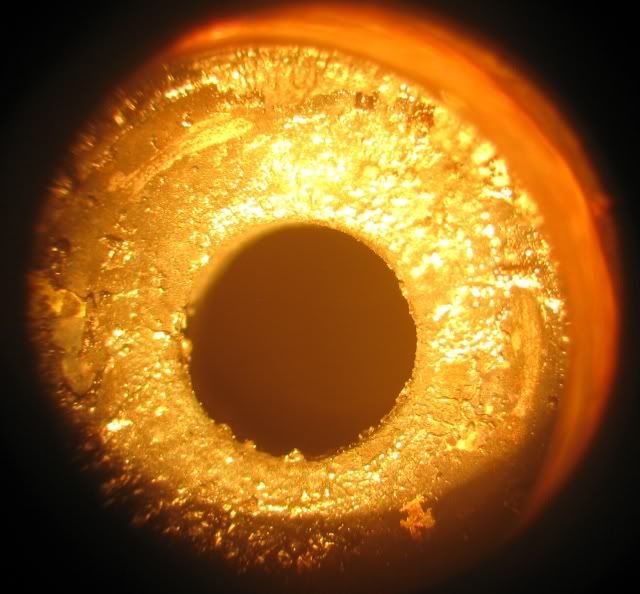

Bolt Face

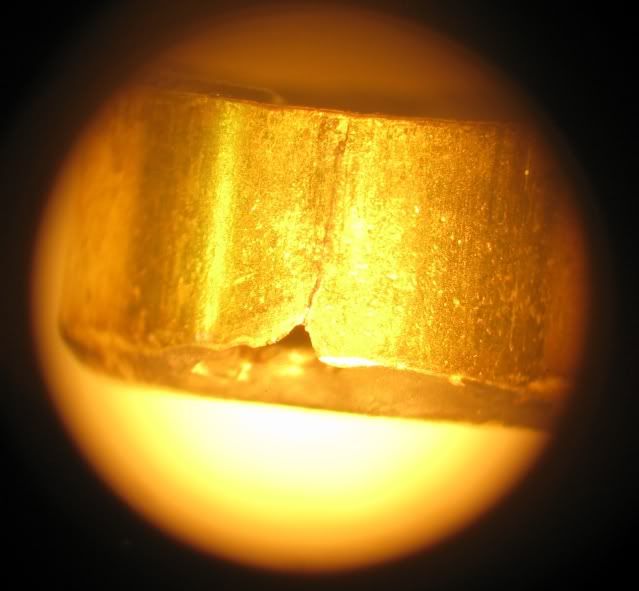

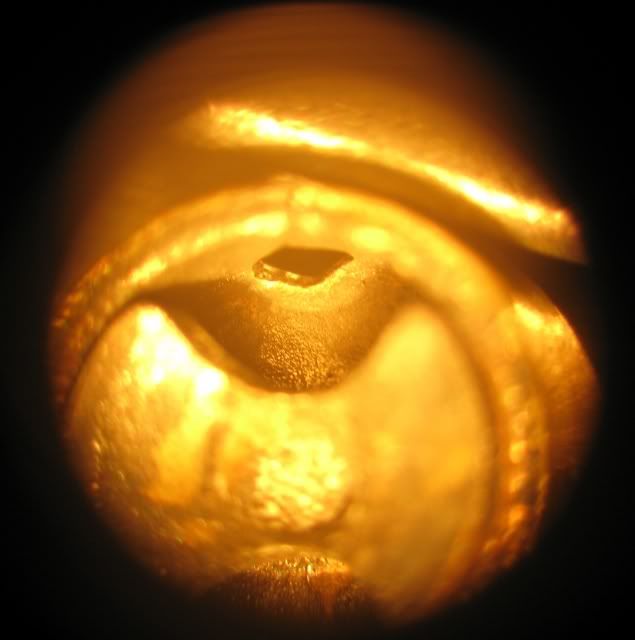

Microscope view of 1st bad primer - still in the primer pocket

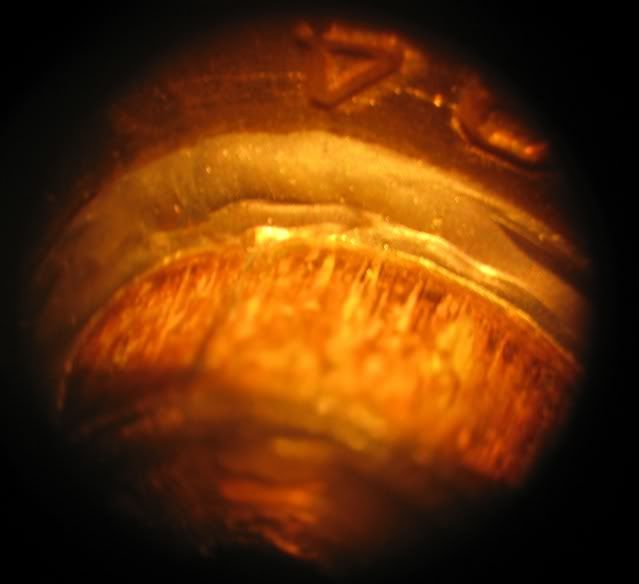

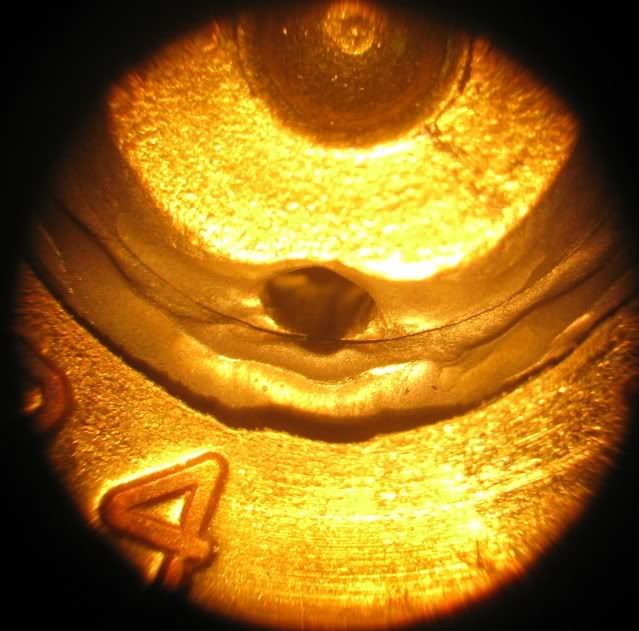

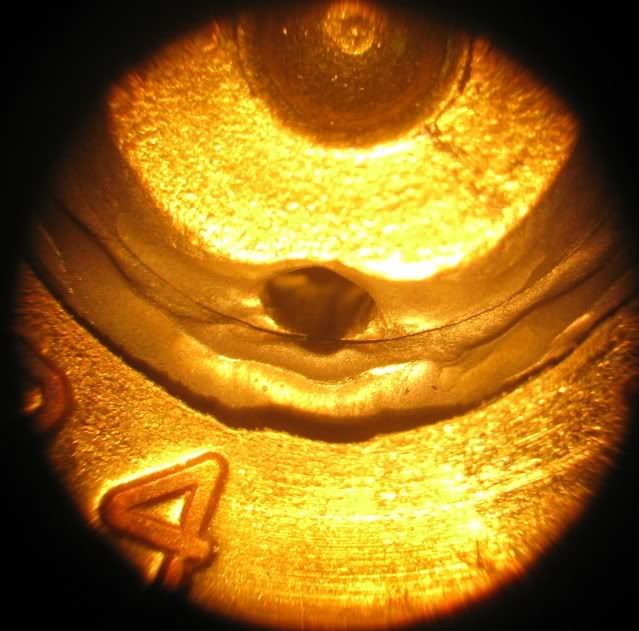

Opposite Side of 1st Bad Primer

Note that the pressure didn't go beside the primer but cut a hole though the cup only. Next Pics will show no was on primer pocket.

More pics to follow.

Thanks.

Larry

So, has this happened to anyone else in this manner (see pics).

I am open to suggestions as I am stumped as to why this happened.

Rifle history and description – I don’t think that it is an equipment problem as of yet but you guys might see or have experience that will mean otherwise:

Surgeon Action, Bedded into McMillian A-5 – Chambered in 6.5x284 (Tight Neck) – Lapua Brass (turned .001 under Chamber Dim.) – 142 Moly Coated Sierra HPBTMK – Seated At the Lands – 53.0 Gr. H4831SC – Jewell trigger – 27” 1:8 Bartlein Barrel – Nightforce 8x32

I installed this barrel about a year ago and it has shot excellent until recently but has started shooting better last couple of outings. I was shooting Federal 215M primers but didn’t want my supply to get too low so I tried the Remington 9 ½ primers since I had read some good things about them. I had aquired about seven hundred Remington 9 ½’s about 10 years ago and thought since everyone’s primer supply hasn’t been too reliable lately, I would see if I could use some them in the 6.5x284.

Well, I loaded up ten rounds with the normal Federal 215M primers, powder & bullet that I have always used plus ten rounds with the Remington primers and went to the range. Shot the first five at 1000 yds. with no problems other than they hit about 14” higher than normal and then the primer blew on the sixth. Looked everything over and didn’t see any abnormal pressure signs or a reason for the malfunction. Shot another – no problems. Shot the eighth round and another primer blew, so I said that’s enough of that.

I’m glad I had my safety glasses on. I shot five with the Federal primers and they all shot very well with no problems so I loaded up and headed home – about a five mile drive.

I didn’t think anything bad had gone wrong until I pulled the bolt to give it a good inspection and could see the damage done by the primers. So I got my microscope out and looked at all of the rounds that had the Remington primers and the Federal primers.

This is what I found. I will post remaining pics in the following post.

Case head - Sorry, I didn't take a pic of the other one but it looked the same.

Bolt Face

Microscope view of 1st bad primer - still in the primer pocket

Opposite Side of 1st Bad Primer

Note that the pressure didn't go beside the primer but cut a hole though the cup only. Next Pics will show no was on primer pocket.

More pics to follow.

Thanks.

Larry