I have read and posted on BRC for several years. I have had both good and not so good responses to my post. I believe Wilbur has a first quality web site. For the most part all readers and posters share a love of shooting.

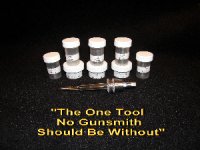

I co-designed a tool with David Kiff for precision measuring when chambering/headspacing a rifle. I have sold a number of them to folks who read and post on BRC. Several months ago Bob Pastor a well respected shooter, reader and poster on BRC bought one of my tools. He called me after getting the tool and we talked for at leats an hour. After he used the tool he made a post on this website to how he was pleased with it's performance. Today in the mail he sent me 11 professionaly done photos of the Micrometer Adjustable Reamer Stop. I would just like to make a public thank you to Bob Pastor. He did not have to do this but it just showes what a quality guy he is.

The shooting faternity is a small one and everybody knows everybody. If one does not take the verbal jousting to seriously, for the most part everyone enjoys the comradery generated on BRC. I have had BRC folks share their knowledge, equipment, components, inventions and more with me.

I just wanted to say that with the world in it's sorry state of affairs, by in large the shooting community on the BRC are a cut above.

Have a great day.

Rustystud

I co-designed a tool with David Kiff for precision measuring when chambering/headspacing a rifle. I have sold a number of them to folks who read and post on BRC. Several months ago Bob Pastor a well respected shooter, reader and poster on BRC bought one of my tools. He called me after getting the tool and we talked for at leats an hour. After he used the tool he made a post on this website to how he was pleased with it's performance. Today in the mail he sent me 11 professionaly done photos of the Micrometer Adjustable Reamer Stop. I would just like to make a public thank you to Bob Pastor. He did not have to do this but it just showes what a quality guy he is.

The shooting faternity is a small one and everybody knows everybody. If one does not take the verbal jousting to seriously, for the most part everyone enjoys the comradery generated on BRC. I have had BRC folks share their knowledge, equipment, components, inventions and more with me.

I just wanted to say that with the world in it's sorry state of affairs, by in large the shooting community on the BRC are a cut above.

Have a great day.

Rustystud