Al,

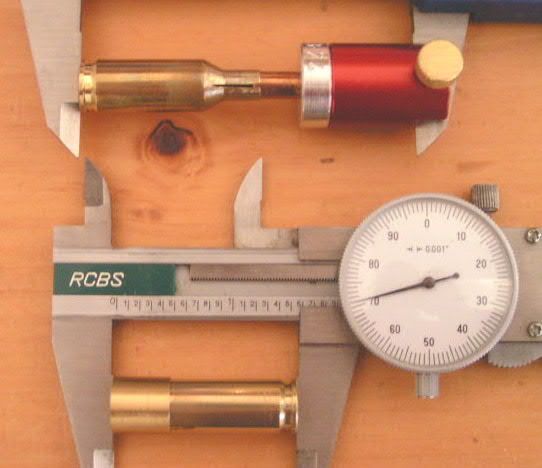

Years ago, with a standard, one piece RCBS die, that had an expander ball (a type that I now scrupulously avoid) , we did the test where we backed the ram down a little after the first trip to the top of the stroke, and turned the case a quarter turn three times, raising the ram to the top after each, and with that setup, there was a measurable improvement in case straightness, we did this several times.

OK Boyd,

I wouldn't keep this going with most guys but I know you enough to respect your opinion AND to know that you really think, you will modify your opinion given a different view or different data.

As will I.

First of all, my real thrust is that manipulating your way into "straight ammo" is completely fruitless without you somehow manage to simultaneously close all your tolerances up at the same time! All the straightness in the world means nothing when you've got 6-8thou of neck slop and a thou or two of endplay.

IMO

That said, let's take the 1/4 turn experiment on it's face..... let's presume that bump-pull/bump-pull/bump/pull/bump-pull DID in and of itself make the round straighter measured on some sort of spin/gaging device. Did the experimenter ever do the test WITHOUT spinning the case? And are we to presume that something was "crooked" in the die? Like the shoulder?

If so, how? How was the die mfd with a tilted shoulder?

And if so, did the case chamber without the spinning? If the experimenter incrementally ironed the shoulder into "flat" by working down the high side was the die set such that the case would not chamber before all sides were worked down?

Now without any widdershinny manipulation a'tall I can guess that ironing a sloppy neck 4 times in a row would tend to work it into some semblence of "straight." It'll also make it fail 2-3 times faster IMO.

Nawww, I can't get behind it regardless of others' findings. Mine have been at odds with many others' claims. Until a mechanism is provided, a reasonable explanation for an increase in concentricity, and until I can duplicate it I can't get with it.

FIT is where I'm at, you promote better fit and you'll actually see an increase in accuracy. "Linearity" and "concentricity," whether achievable thru manipulation or not, are irrelevant EXCEPT to gauge the fitness of your system. If your system isn't producing perfectly straight ammo then the problem is FIT of components not "linearity." Besides, the idea of "producing linearity" with sizing dies is ludicrous when springback is considered. Brass must be bent or forced well past where you want it for it to spring back to the desired dimension. IF the caseneck were somehow bent over a thou by the die you'd have to turn around and bend it back two thou for it to (maybe) come back to center. And my experience with bending ammo into "concentricity" using the various tool available has shown me that to straighten ammo takes a whole lot more than subtle .001 tweaks!

But that's still missing my point.

Until I'm convinced differently my view of the firing cycle shows the case completely blown out against the chamber walls, completing it's function as a sealing gasket BEFORE THE BULLET ENTERS THE LANDS......the back of that bullet is just hanging there unsupported until pressure builds sufficiently to engrave it into the bore... therefore it WILL be slammed against one wall or t'nuther, entering the lands crooked.

Straight ammo don't mean nuttin' in a loose chamber.

opinionsby

al