To the OP,

I'll share what I learned after buying different tools and inserts to achieve what I think is an improvement from when I started. I finally settled on the Arthur Warner 35 degree tool, but instead of using the HSS insert that came with the tool, after trying different ones, I settled on these inserts, VCGT 110302-AL K10 for Aluminum (VCGT 220.5). That is the description on eBay.

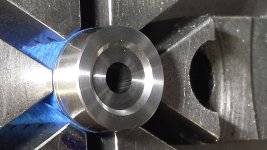

Here is the Arthur Warner Tool and a sample of the recessed target crown I do on AR barrels. Unpolished, done on a set thru 6J. Spinning the spindle fast and making shallow cuts. I use the same set cutting bolt nose recess. Remember this is just a job by a rookie, it may not meet the standard for most of the people here, but it is about all I can do at the present with my skills.