There's some controversy on whether a bullet that's jammed hard into the lands can actually keep the case head in contact with the bolt face during firing. Lots of shooters, myself included, use this process when fireforming and/or blowing shoulders forward on various wildcats. Whether or not this happens is pretty easy to demonstrate. After reading one particular thread, I decided it was time to post some pics of the deal. The test mule is my RFD 30BR.

-First, I removed the priming compound from a new Fed 205 primer. The priming compound is the yellow-ish stuff. The anvil was left in the primer so as to replicate things as best I could.

-Next, I f.l. sized a case normally with the same bushing that I always use in this gun (.003 neck tension). Shoulder 'bump back' is .0015. 'Dud' primer is seated.

-Firing pin is removed from the bolt. Bullet is seated with .020 'jam', as per usual with this gun.

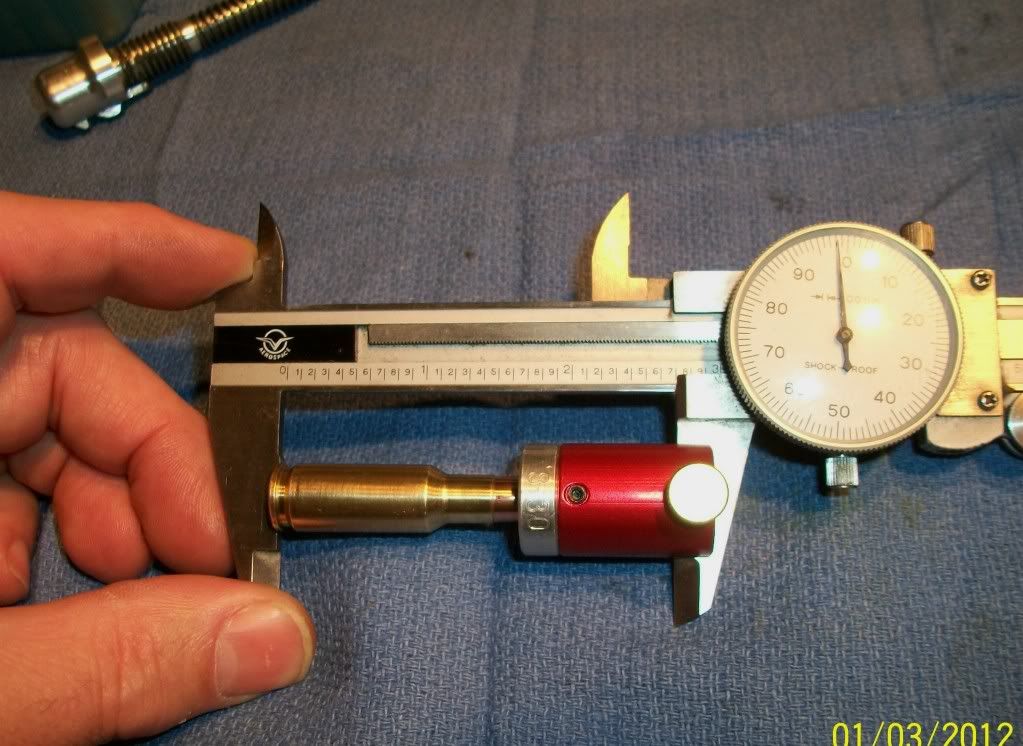

-Case head-to-ogive measures 1.698 on the seated bullet. Again, this seating depth is a .020 'jam'.

-Dummy round is chambered, then extracted. The rifling marks from the bullet being 'jammed' .020 are very pronounced, as you can see in this pic.

-The case head-to-ogive is again checked to see if it's changed after being extracted. It's still 1.698. Again, the rifling marks are visible.

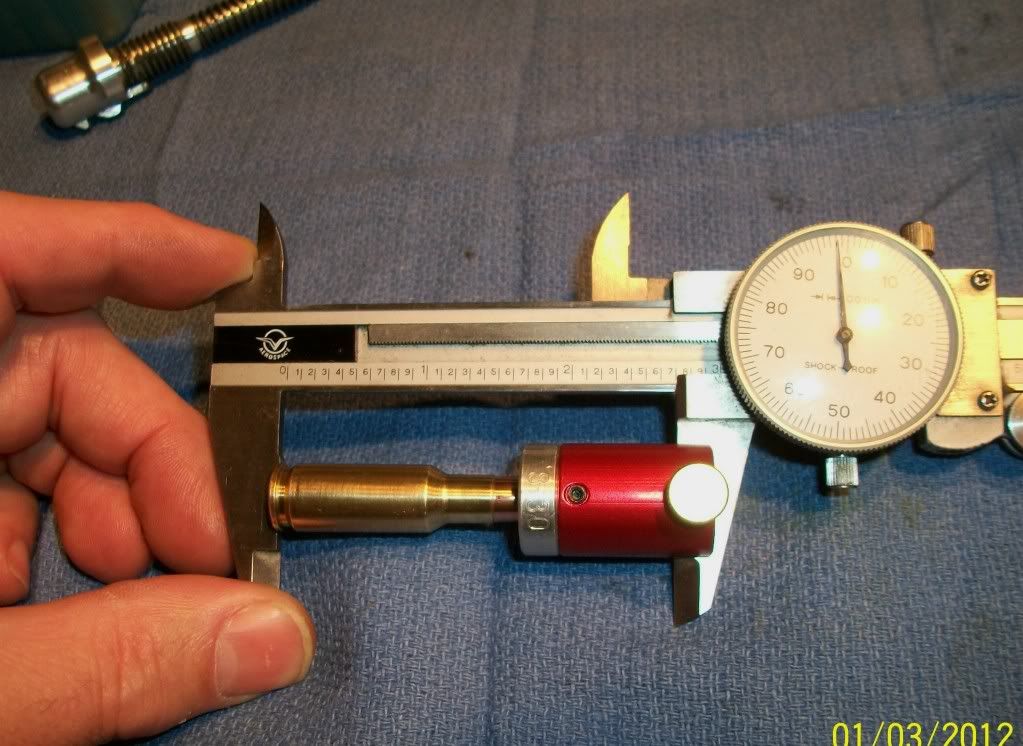

-Firing pin assy. reinstalled, trigger pulled and round extracted. Case head-to-ogive measures 1.695.

So, at most, the bullet pushed back into the neck .003 (1.698-1.695). Given that the shoulder was back .0015 from the sizing process and the case can move forward in the chamber that much when the pin hits the primer cup, what we're really seeing is a .0015 bullet 'push back' into the case neck.

Connect dots accordingly..............

Good shootin'. -Al

-Al

-First, I removed the priming compound from a new Fed 205 primer. The priming compound is the yellow-ish stuff. The anvil was left in the primer so as to replicate things as best I could.

-Next, I f.l. sized a case normally with the same bushing that I always use in this gun (.003 neck tension). Shoulder 'bump back' is .0015. 'Dud' primer is seated.

-Firing pin is removed from the bolt. Bullet is seated with .020 'jam', as per usual with this gun.

-Case head-to-ogive measures 1.698 on the seated bullet. Again, this seating depth is a .020 'jam'.

-Dummy round is chambered, then extracted. The rifling marks from the bullet being 'jammed' .020 are very pronounced, as you can see in this pic.

-The case head-to-ogive is again checked to see if it's changed after being extracted. It's still 1.698. Again, the rifling marks are visible.

-Firing pin assy. reinstalled, trigger pulled and round extracted. Case head-to-ogive measures 1.695.

So, at most, the bullet pushed back into the neck .003 (1.698-1.695). Given that the shoulder was back .0015 from the sizing process and the case can move forward in the chamber that much when the pin hits the primer cup, what we're really seeing is a .0015 bullet 'push back' into the case neck.

Connect dots accordingly..............

Good shootin'.