Long !!

Here is the bbl that is on my 40X at the moment. I bought a couple of used bbls for a 2013 and this one was said to be a Shilen. It was only about 21" long and it had a .920 OD which was worrisome [ 10/22 normal "match" bbl OD ]. I borescoped it and it did look smooth enough to be a Shilen. I don't like short bbls so I never tried it on the 2013 which was eventually sold.

The 40X was my first bbl fitting project and it's normal bbl is an Anschutz Match blank that Numrich sells. These blanks are 1.25" OD straight , no taper. The bore is SMOOTH. It is also straight with choke at the muzzle. A pulled bullet slides with almost no resistance after you get beyond the leade.

I shot the bbl as a straight cyl for quite awhile. It would shoot good groups but threw too many fliers. Eventually I bought the borescope and discovered what I call 'boat paddle' burrs on the rifling which turns out is normal from what I have seen with other bbls I have looked at. I used a split arbor and 600 paper to eliminate the burrs and then the bbl would really shoot some great groups. Still would throw the occasional ammo induced small flyers but no more 7s or worse.

I then turned the OD down to .825 so I could use a tuner on the bbl. I left a full dia torque shoulder and when slugging I could feel a constriction at the shoulder. Hmmm. I then turned off the shoulder and extended the tenon threads and now use a Pacnor nut to secure the bbl. This also gives adjustable headspace.

Now back to the .920 bbl. I turned down the 2013 bbl tenon to .645ish to use in a 40X bbl tenon that I extended the threads on for use with the Pacnor nut and I bored the ID to .645ish. I used Loctite 609 to secure the bbl to the tenon. I did NOT slug the bbl. When I had borescoped the bbl earlier I did notice that the leade looked perfect which was surprising and encouraging. I did not slug the bbl. The gun shot extremely poorly so I removed the bbl and ignored it for a few weeks. Then while slugging other bbls I decided to slug this bbl. The slug had slight resistance all the way down which tells me the bore is slightly tapered as is the norm on state of the art rf aftermarket bbls.

When the slug got to the muzzle it STOPPED. It had to be hammered on through

. Obviously the person that did the original bbl work did not cut off enough of the blank. I cut off 1/2" and tried it again. Still too tight. I cut off another 1/4" and redid the crown.

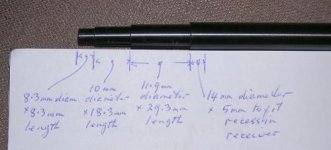

In thinking about this set up I decided I didn't like having the weight of the full .920 bbl hung off that .645" dia tenon. I also wanted to induce a bit more taper to the bore so I came up with the dimensions needed to have equal length sections with equal diameter change for each segment. Basically the segments are 3" long and enlarge by .050" OD segment by segment. This ends up with the last 3" segment at the muzzle being the original .920" OD so I don't end up with the bore dimension growing at the muzzle. In other words I retain the smallest possible ID in at the muzzle.

When slugging the newly turned bbl it did seem to have slightly more drag on the slug. Not a tremendous amount but some more than the original straight contour. The constriction at the muzzle still seems tight to me but not excessive as before.

I shot the rifle after our last match and the thing showed a lot of promise in the short time I had available. I shot one group of 8 to 10 shots at one RBA sighter bull and all shots were clustered around the 10 ring. Not a tiny group, but all solid 10s. This is with no tuner.

I came home and made a sleeve [ about .010" wall thickness

] to allow the mounting of a Fudd tuner I have. I will shoot the gun some more on Thursday morning if the weather cooperates.

I have a couple of Benchmark bbls that came with a rifle and both shoot very well with Center X. One of these bbls is a short 3 groove, RF BR reverse taper sporter bbl that is about 21.5" long. It shoots very well even though it is short for my tastes. It is VERY draggy when slugging as is the other Benchmark reverse taper. I was trying to duplicate this draggy slugging feel with the 'telescope' turning of the bbl in the pic.