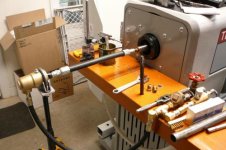

Dave your next investment...

Dave:

Go to one of the race team shops over in Charlotte and get their shop to give you a demonstration of Gibbs Cam/Solid Works. If you know how to run a CAD program it will give you an instant up on the learning curve. Knowing a little geometry and trig will also help. Understanding basic machining also is a big help understanding the tooling part. Advance machining and the use of a universal indexer will give you a fundamental understanding on machining in the 4th and 5th axis. Anyone can machine the X, Y, Z axis. Straight lines are easy on a manual machine. The advantage of CNC is now you can cut in an arc, on a bevel, and a compound angle at the same time. Cuts on a piece of stock can be cut in precision relationship to each other and it duplicated over and over again.

My money would say that the CNC bug has bitten and your next two investments will be: 1. A good (Gibbs CAM) CNC computer program for writing G code, tooling, solid works (modeling/testing) and machining. 2. A 3 or 4 axis vertical mill (maybe a HAAS VF 20).

If your community college offers Machining classes including CNC Programing you might be well served taking a couple of classes. It will accelerate your learning curve. In 3-4 semesters your knowledge and skills will pay for themself in a month or less. For a couple of years I signed up for basic machining, the instructors knew my skill level and allowed me to work independently of the class. I had a million dollar shop to my disposal since the class (students) was all using the manual machines. I could not lease the equipment I had to my disposal for the cost of the class.

Be safe and make a lot of chips..

Nat