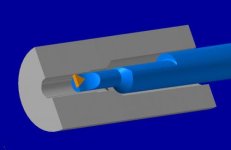

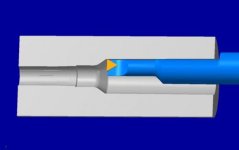

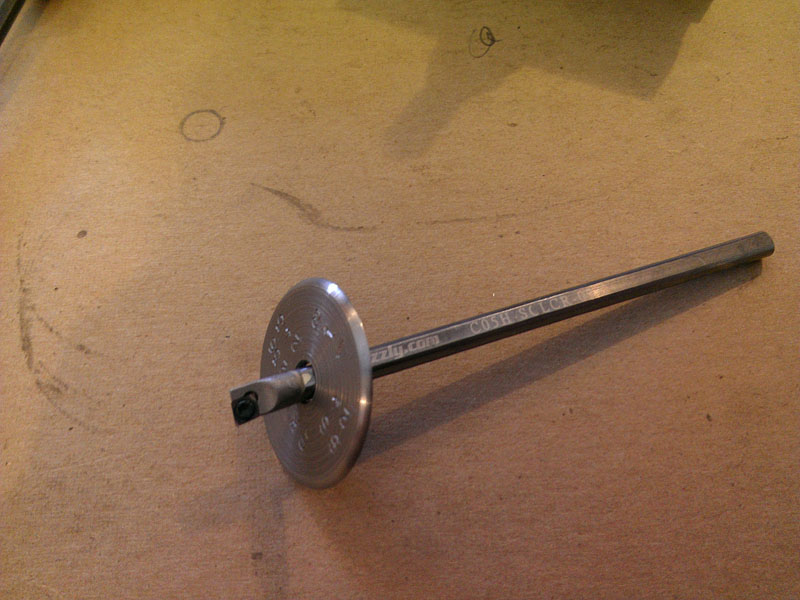

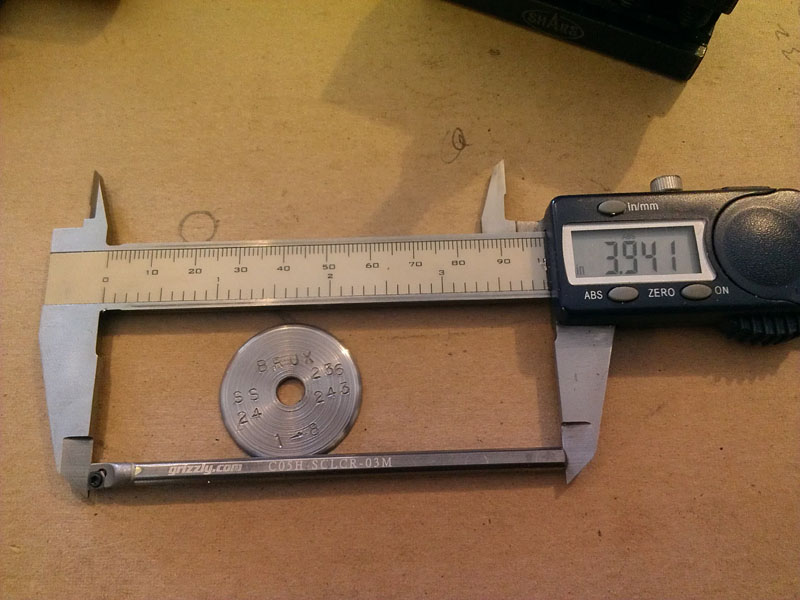

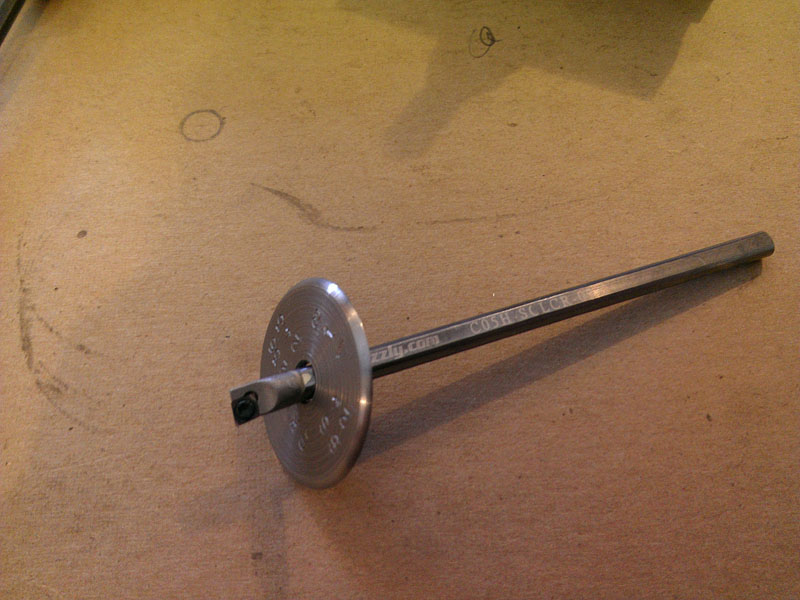

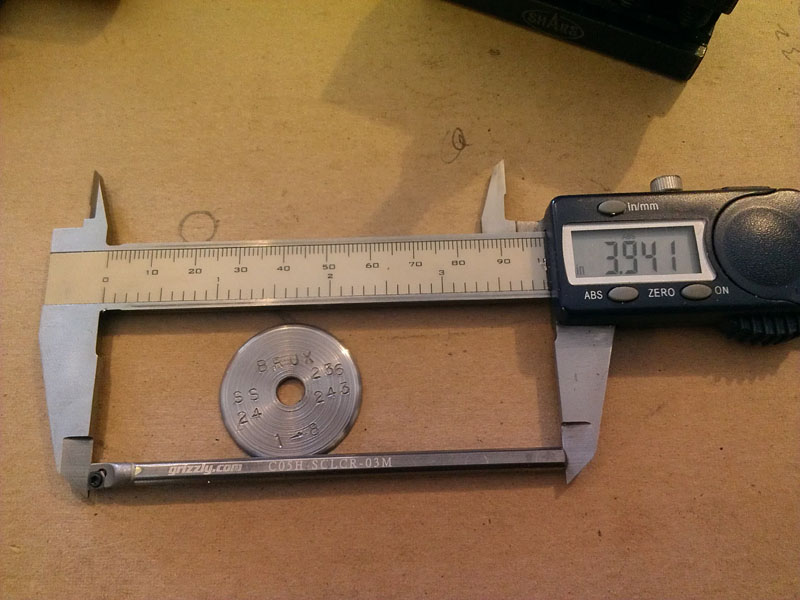

I picked up this Grizzly boring bar. Min bore is .236. Will work great for boring muzzle brakes, pre boring chambers, boring a seater stem hole, etc. Figure this might be use for others that are looking for a small minimum bore boring bar that that has enough length to make it very useful! Every mini boring bar I find with a small min bore will only bore 2" deep or so. This one has some length to it!

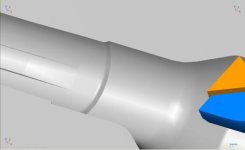

Overall the bar is very nice quality. About the only inserts I can find for it are made by Mitsubishi and are only sold in packs of 10.

http://www.carbidedepot.com/detail.aspx?ID=298890

Overall the bar is very nice quality. About the only inserts I can find for it are made by Mitsubishi and are only sold in packs of 10.

http://www.carbidedepot.com/detail.aspx?ID=298890

Last edited: