N

NesikaChad

Guest

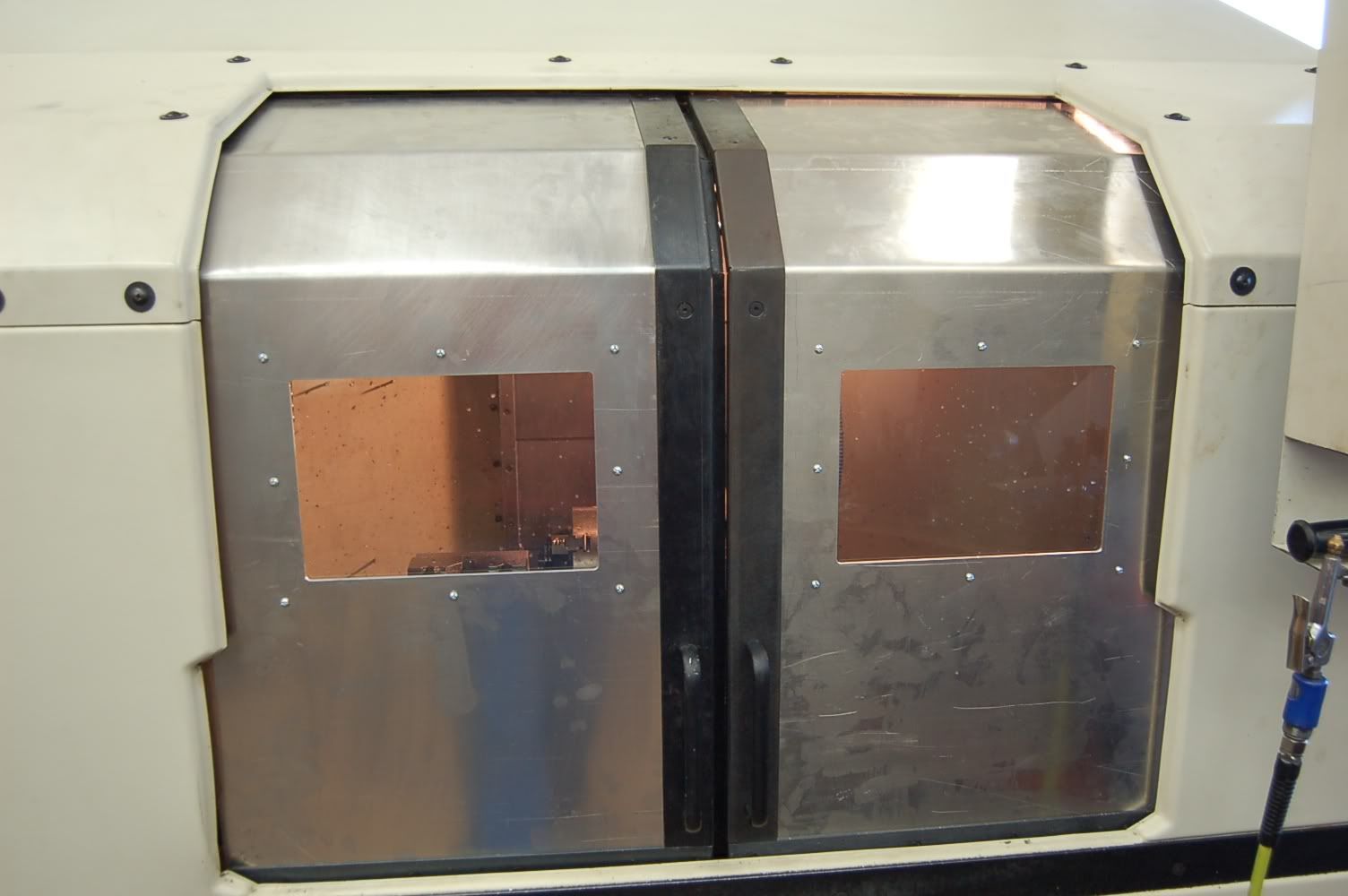

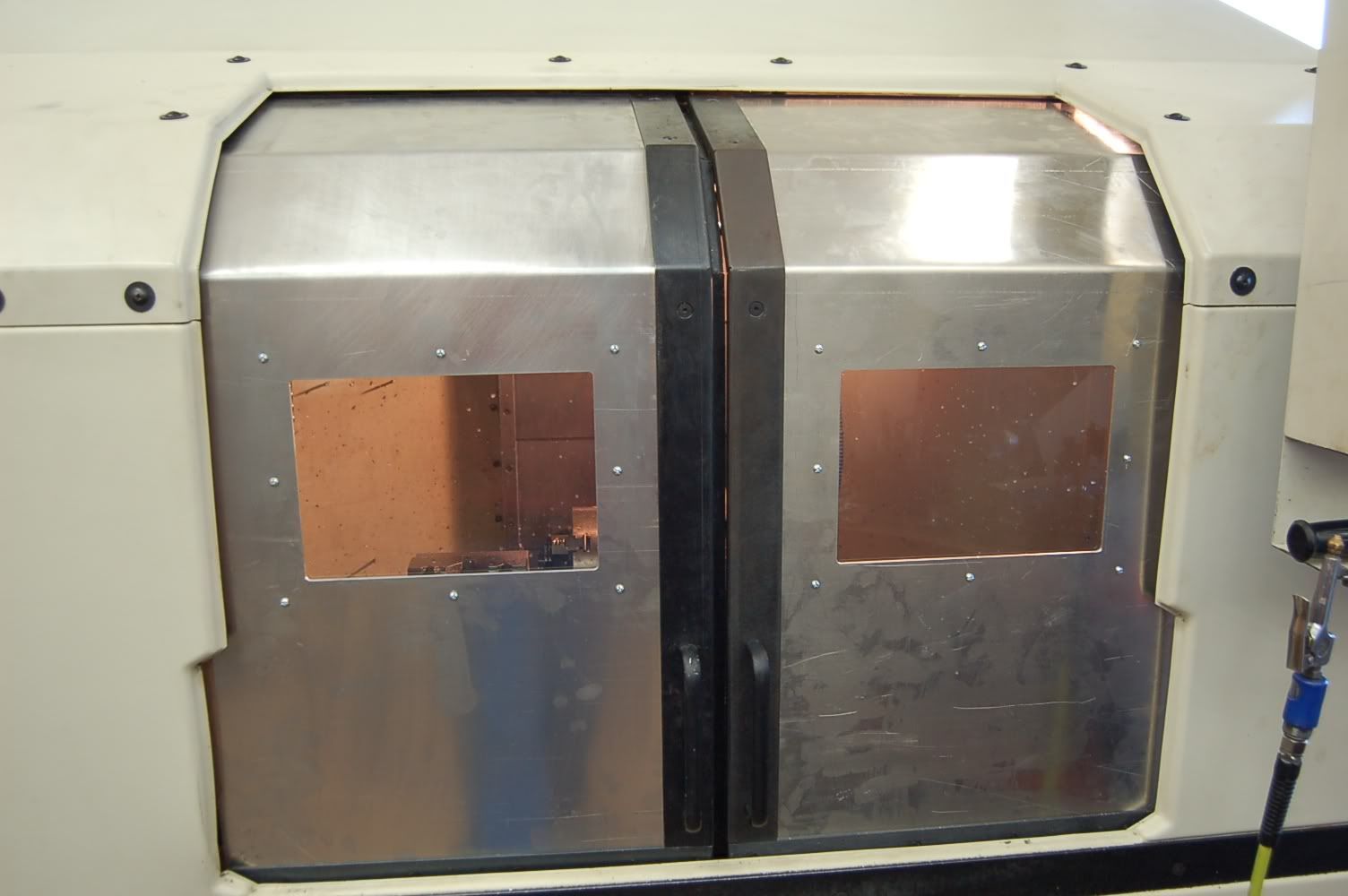

I gotz (purchased) my old fixtures from Nesika last Friday. I made all these about six years ago when I first got there. Just spent the afternoon tearing them down, cleaning them up, chasing all the tapped holes and reassembling.

Me'sa very, very happy right now as it means I don't have to make this $%#@ all over again. See that last photo? NO BEDDING in the floor metal. One to one fit! Love that!

Woo Hoo!!

Me'sa very, very happy right now as it means I don't have to make this $%#@ all over again. See that last photo? NO BEDDING in the floor metal. One to one fit! Love that!

Woo Hoo!!

Last edited by a moderator: