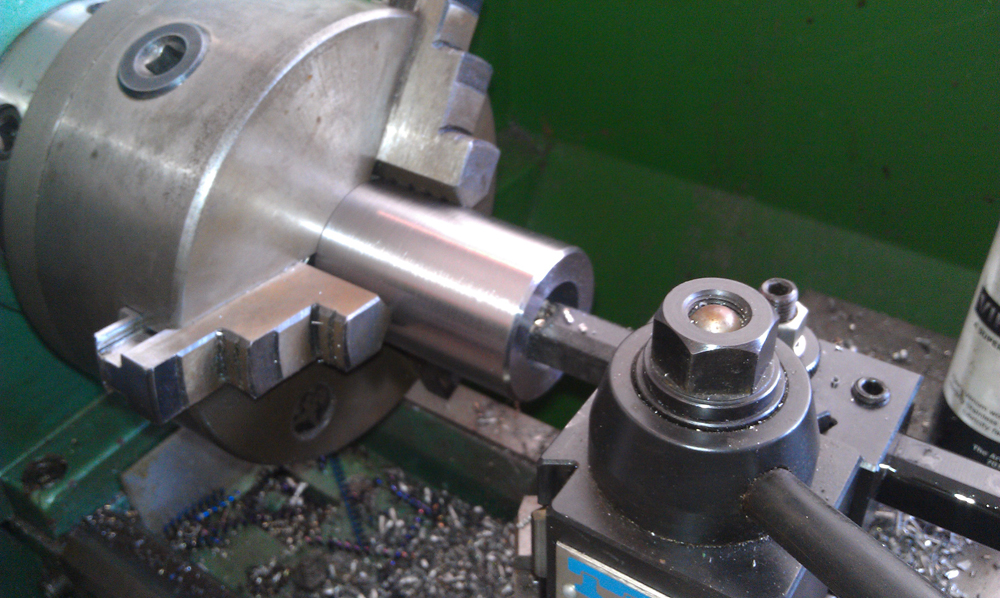

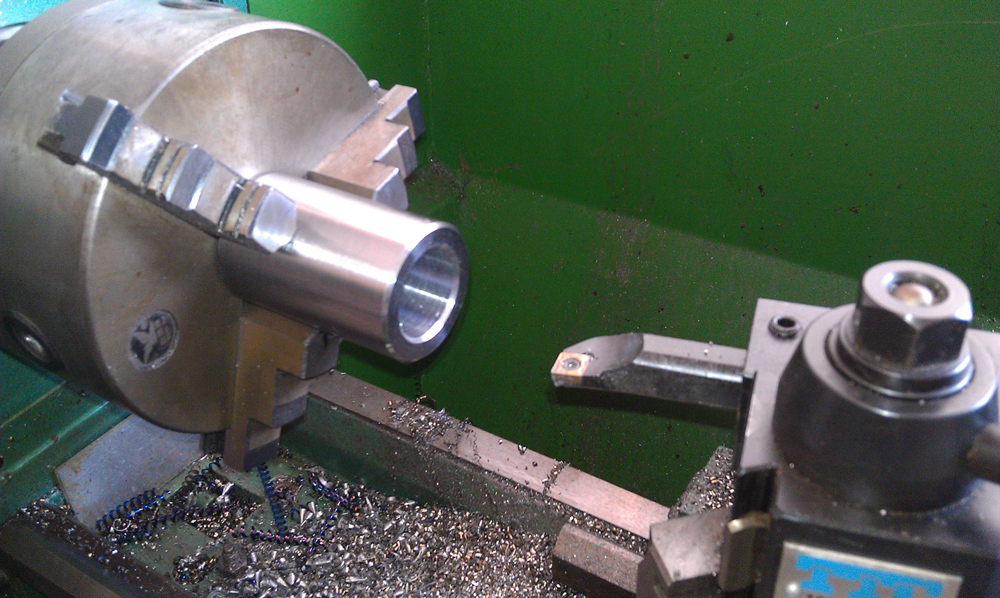

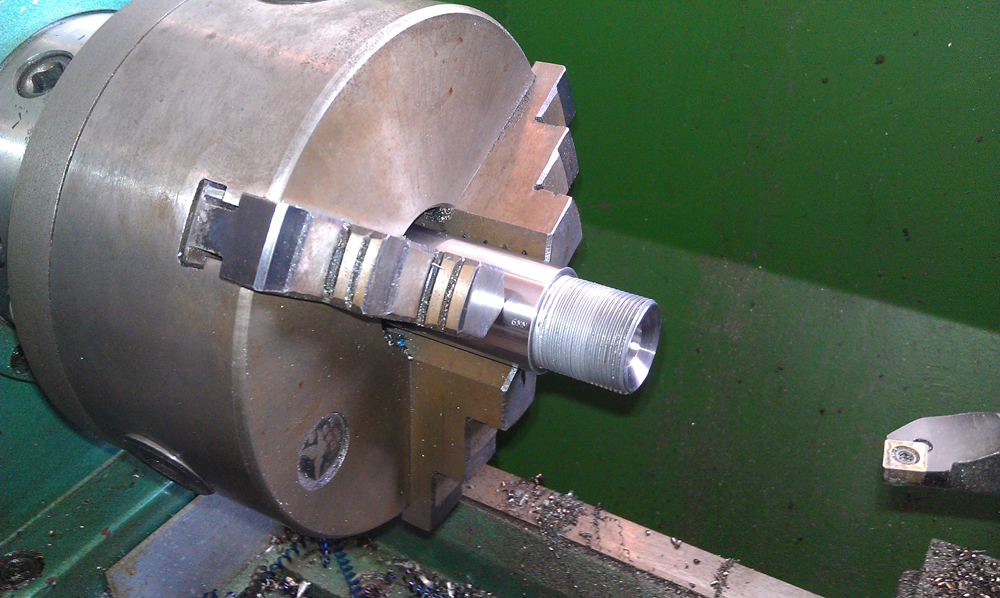

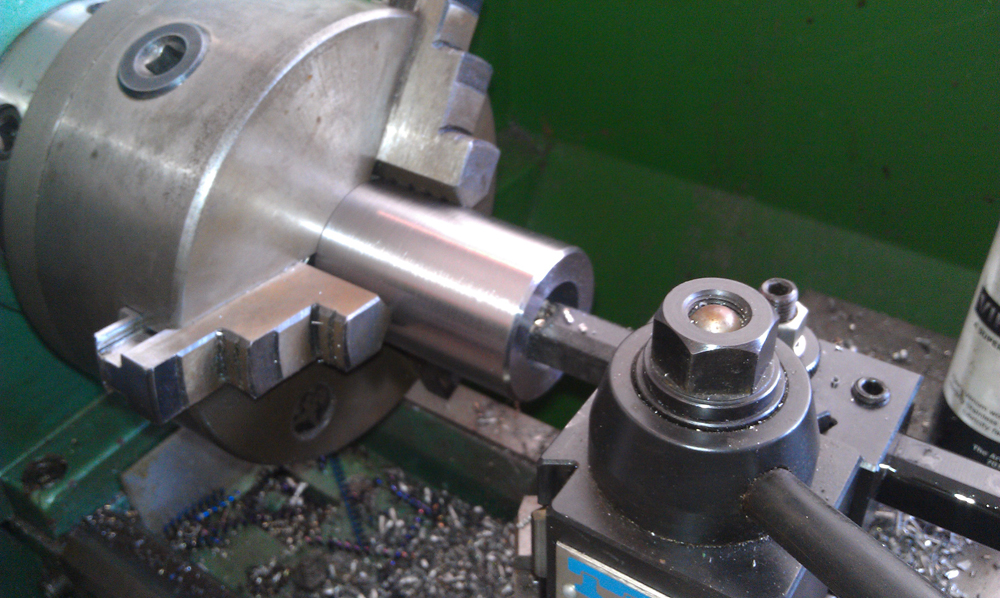

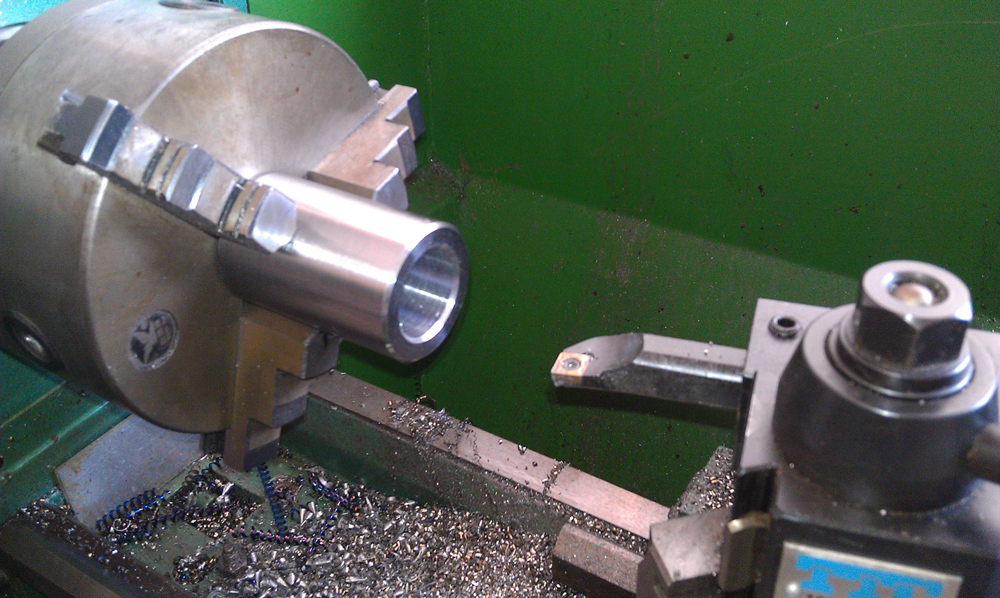

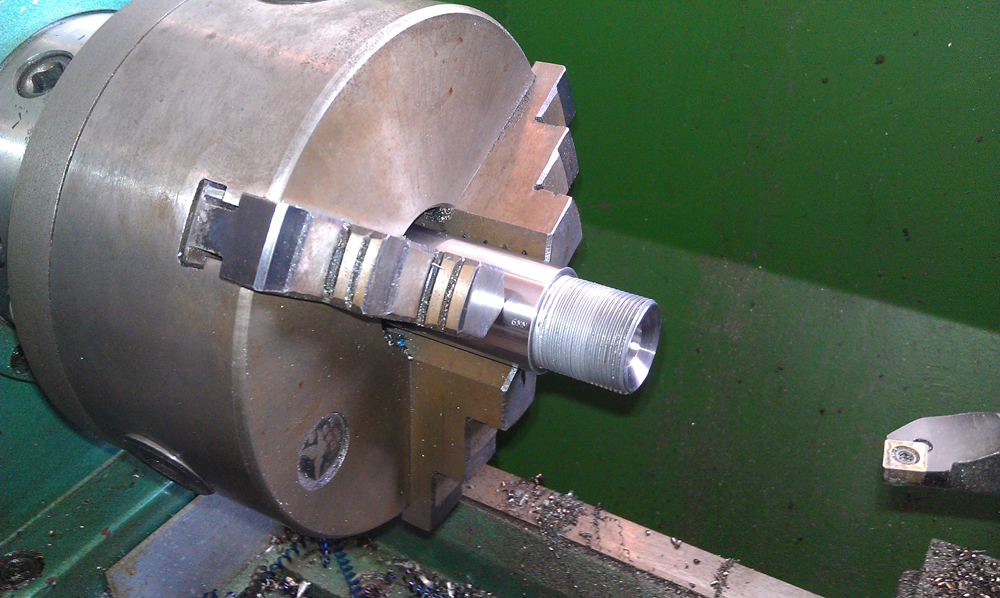

Started out with 2.5" solid bar. Turned it down to roughly 2". Turned the diameter of the step and inside diameter for a super snug fit in the spindle bore. Drilled a 3/4" hole all the way through and finished with a boring bar. Came out great!

Now, I do have a quick question. I do not have a mill and I need to drill and tap the 4 holes for the brass tipped cap heads. Any suggestions? Would it be possible to do it on my drill press if I clamp and square in V blocks? I want my tap to start straight, any suggestions?

Now, I do have a quick question. I do not have a mill and I need to drill and tap the 4 holes for the brass tipped cap heads. Any suggestions? Would it be possible to do it on my drill press if I clamp and square in V blocks? I want my tap to start straight, any suggestions?