Crow,

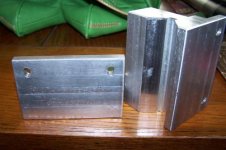

In the attached picture, you can see the aluminum v-block vise jaws I made for my New Hermes TX. My engraver's jaws have 4 dowel pins that stick up on top, 2 from each jaw. The holes in the tops of the pictured jaws fit over the top of these pins and hold them in place. I got the idea to use the dowel pins to index the jaws from a Butch Lambert posting. I shamelessly copied his idea...

When doing the chambering engraving, I pad the jaws with pieces of leather I have laying around and grab the action. This works on 700's. I haven't tried it on any other actions. When I'm engraving farther down the barrel, I grab the barrel where I will be engraving. The jaws leave me a window of space between them to get the drag tool in there. Because of the taper, you may have to build up the smaller side of the barrel a bit to get things nice and straight.

So far, the jaws and method have worked out perfect for me.

Something else I do is bolt up the barreled action in the stock, laying an 1/8th parallel I have on top of the barrel channel, and scribe a mark with a pencil down the length of the barrel a ways. This mark, which runs parallel with the top line of the stock becomes my "is it square to the world" reference, as well as the lowest point of the engraving, i.e., with the pencil mark left on after engraving, it would look like this:223 Remington. Hopefully, I explained this OK.

Hope it helps,

Justin