You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

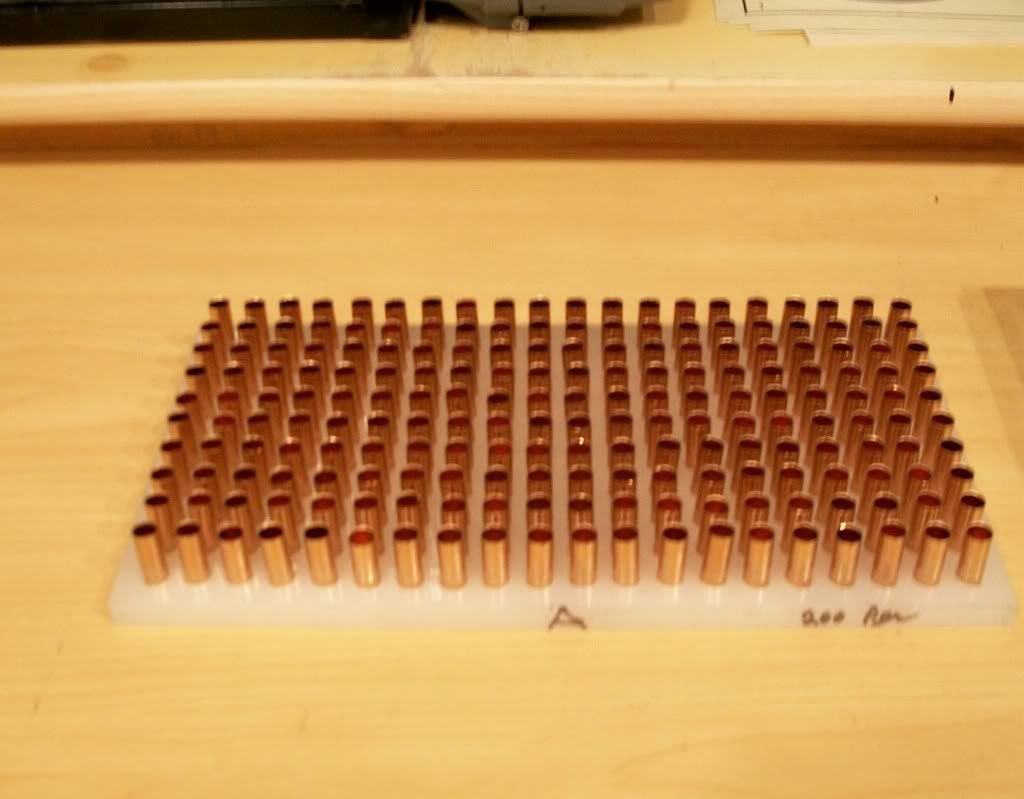

Bullet making trays

- Thread starter Joe Duke

- Start date

C

caroby

Guest

Nice pics Al, do you get say "most" of the jacket going the "right way" up when working jackets into the jacket trays..?

My trays, I get about 10-20 percent that like to go the wrong way get out the tweezers

get out the tweezers ..... My trays hold 150 at a time.

..... My trays hold 150 at a time.

cale

My trays, I get about 10-20 percent that like to go the wrong way

cale

Joe Duke

Active member

So, if I understand:

1. You set the jackets in tray B and shake them to get them all in a hole and turned upright; using tweezers on the stubborn ones.

2. Let them fall into tray A.

3. Set the cores all in tray B?

4. Let them fall into the jackets that are in tray A

5. Make bullets. :>)

Joe

1. You set the jackets in tray B and shake them to get them all in a hole and turned upright; using tweezers on the stubborn ones.

2. Let them fall into tray A.

3. Set the cores all in tray B?

4. Let them fall into the jackets that are in tray A

5. Make bullets. :>)

Joe

R

rossi

Guest

Hello,

are the trays jacket specific or suitable for different lengths?

are the trays jacket specific or suitable for different lengths?

Mike Bryant

Active member

Below are links to Walter Carraway's article on making a set of bullet making blocks that was printed in the NBRSA News in October 1994. Walter used plexiglass to make them, acetyl sheet would probably work better as it would be easier to drill and work. I made a set of them with a manual mill without digital readout about that time using his article's instructions. Walter was getting $250 at that time. He earned every penny if he was using a manual mill. With a CNC mill, it would be simple.

Walter Carraway article pg. 1

Walter Carraway article pg. 2

Walter Carraway article pg. 1

Walter Carraway article pg. 2

R

rossi

Guest

Thanks for the feedback, very interesting article.

I’ll try to make some for .30 jackets.

I’ll try to make some for .30 jackets.

R

Roger Ronas

Guest

What size holes would be needed for 22lr jackets and the cores to make .226 bullets?

Thanks

Roger

Thanks

Roger

Mike Bryant

Active member

Roger, I've used the ones that I made from Walter's article for both 6mm and .22 bullets. So, same size should work for .226 bullets.

R

Roger Ronas

Guest

Thank you Mike

U

Utah Shooter

Guest

Could I please bump this? I am actually looking to purchase some but this thread is about the closest that I can find.

W

WFR69

Guest

Laser Work

My wife does laser work if anyone is interested.

Deer Park Laser

713-569-1110

Don't know for sure, but have a hunch that a 100W CO2 laser engraver could make short work of bullet trays and loading blocks. I was gonna buy one years ago but faltered at the cost.

My wife does laser work if anyone is interested.

Deer Park Laser

713-569-1110

Joe Duke

Active member

Could I please bump this? I am actually looking to purchase some but this thread is about the closest that I can find.

Back when I was looking for these, I think I figured out that no one was making them for sale due to the labor involved. Most who have made them only made one or two sets for themselves and maybe a close friend. A CNC mill should help a bunch if one wanted to make them.

Joe

Joe Duke

Active member

My wife does laser work if anyone is interested.

Deer Park Laser

713-569-1110

Will the laser burn holes in thick plexiglas?

See post #3 for example.

Joe

geo.ulrich

Member

Back when I was looking for these, I think I figured out that no one was making them for sale due to the labor involved. Most who have made them only made one or two sets for themselves and maybe a close friend. A CNC mill should help a bunch if one wanted to make them.

Joe

not sure where your getting your info. but I've been making for a number of years.george