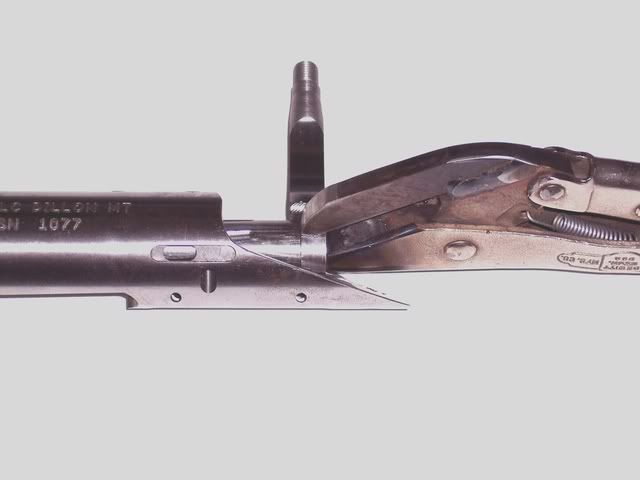

I think that most people make their own alignment fixture for welding or brazing the bolt handles in place.

I made a tooling aid that allows me to determine the distance from the front of the bolt handle notch to the lug abutments. It is similar to a barrel stub, 1.500 in length. It is threaded all the way except for a short flange at the front which is the same diameter as the receiver. The threaded end bottoms out on the lug abutments and you can use a caliper to measure front of notch to end of "barrel stub". Subtract 1.500 and you have a minimum dimension to use when attaching the handle. My fixture allows me to measure the parts when clamped in place.

I'm not sure about the 1.500 dimension but it is not really relevant, just so that it is long enough to function.