H

henrya

Guest

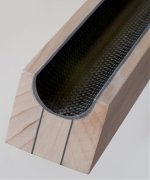

I've made definite progress on my stock blank project. Here are photos of the first "production" blank before the carbon fiber barrel channel has been molded. I'll have photos showing the finished blank with the completed molded channel in a day or two. This redwood stock will get a strip of 1/2" redwood each side of the forearm to make the 3" width.

I'm leaving the blanks as a basic beam to make it easier to hold for the work that follows - cutting the trigger and guard mortises and any guard screw or pillar holes. The toe section can be variable in size and configuration. For a real low profile stock the "toe block" shown here attaches after inletting. About any toe configuration is possible by making a toe block to suit. If the stock was going to be cut on a duplicator I'd glue it up one piece.

I'm also making cherry and walnut blanks that'll be nice for HV or long range guns.

I'm leaving the blanks as a basic beam to make it easier to hold for the work that follows - cutting the trigger and guard mortises and any guard screw or pillar holes. The toe section can be variable in size and configuration. For a real low profile stock the "toe block" shown here attaches after inletting. About any toe configuration is possible by making a toe block to suit. If the stock was going to be cut on a duplicator I'd glue it up one piece.

I'm also making cherry and walnut blanks that'll be nice for HV or long range guns.

Attachments

Last edited by a moderator: