You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrel spinner/ polishing aid

- Thread starter skeetlee

- Start date

I'd look at this spinner opposed to the Brownells version. Much better quality. You could always build one as well...

http://www.longriflesinc.com/products.html

http://www.longriflesinc.com/products.html

alinwa

ill take your word for it as these look like a great product and idea.

What grit of paper should one use? 320, 400?? Chads article talked about getting hit in the face with a barrel. I am assuming the speed at witch the belt turns comes into play. I am also assuming one would use his hand as a brake against the barrel, so it doesn't get out of control. lee

ill take your word for it as these look like a great product and idea.

What grit of paper should one use? 320, 400?? Chads article talked about getting hit in the face with a barrel. I am assuming the speed at witch the belt turns comes into play. I am also assuming one would use his hand as a brake against the barrel, so it doesn't get out of control. lee

alinwa

ill take your word for it as these look like a great product and idea.

What grit of paper should one use? 320, 400?? Chads article talked about getting hit in the face with a barrel. I am assuming the speed at witch the belt turns comes into play. I am also assuming one would use his hand as a brake against the barrel, so it doesn't get out of control. lee

Yeahh.... barrels are wicked crooked.

Crooked means out of balance.

Barrels are also flexible.....

You get the barrel spun up and alla'sudden she goes ballistic on ya'......... like a buzzing bearing, and the barrel will pop right out of a non-rigid holder.

So, yes, you brake with your fingers but there's a fine line, fast spin makes for fast work.

I use all the grits and end up on a wheel....

al

Wayne Shaw

Active member

Can't you control the rate of spin by angling the barrel to the cutting surface? Perpendicular would cause a direct spin, where if you tilt the barrel so the cut is along the barrel should reduce the "spin". No?

MilGunsmith

Member

Wear a heavy leather glove for a brake. Speed changes depending on angle to belt.

JerrySharrett

Senile Member

IMO, these between-centers barrel spinners are a great way to prepare lunch...if you like to eat barrels!!

E

eww1350

Guest

IMO, these between-centers barrel spinners are a great way to prepare lunch...if you like to eat barrels!!

+1 on what Jerry says...I do it the old fashioned way in my lathe....I plan on someday using a modified wood lathe and a crankshaft polisher...when my ship comes in..

Eddie in Texas

B

bcrifles

Guest

I purchased a new belt sander, so now I need to buy or make a barrel spinner. Im looking for ideas on how to make one of these. I see brownells sells one. Is this design a decent one? Anything will help. thanks Lee

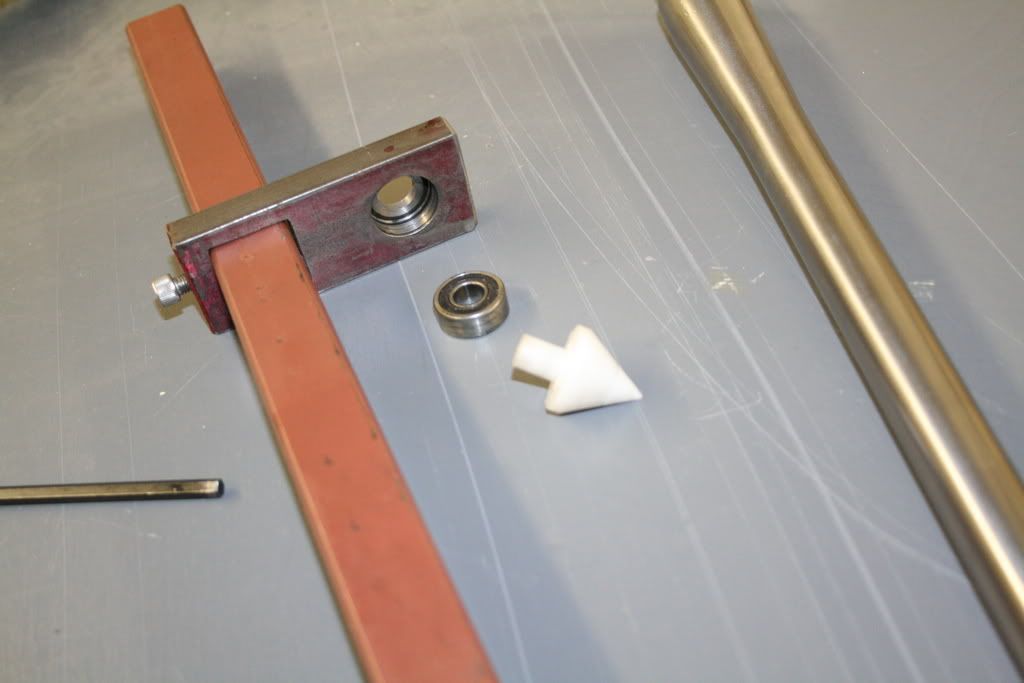

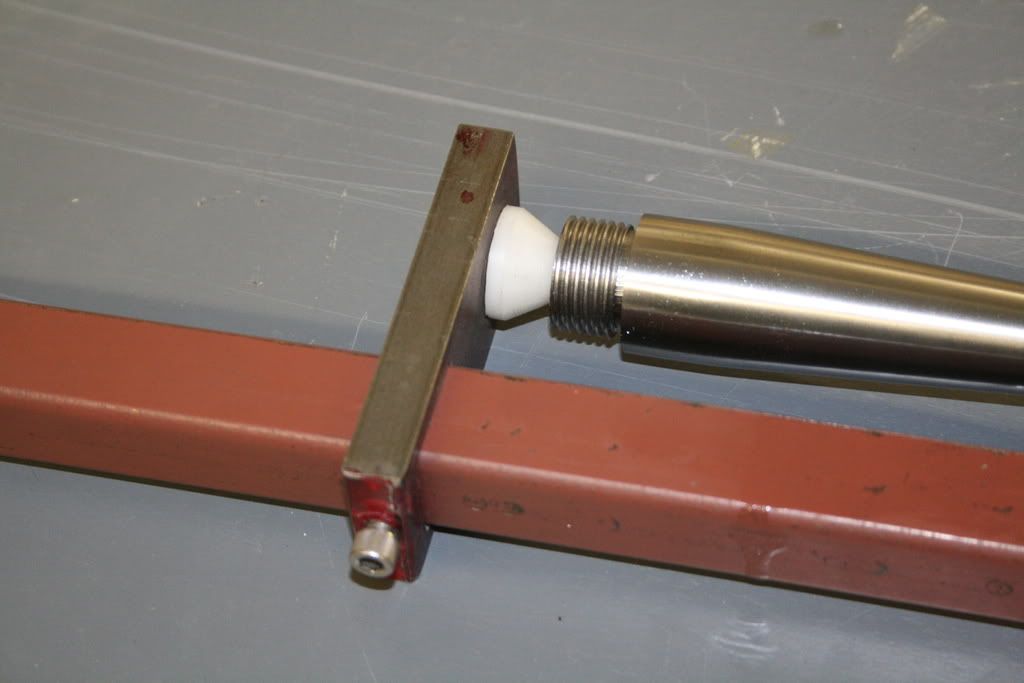

Lee you can make one quite easily out of a piece of square tubing steel or aluminum and 2 old live centers make adjustable brackets for the centers that attach to the tubing then widdle out some protective center tips to protect the crown works just fine Brian

I purchased a new belt sander, so now I need to buy or make a barrel spinner. Im looking for ideas on how to make one of these. I see brownells sells one. Is this design a decent one? Anything will help. thanks Lee

I made one several years ago that I am still using in my shop. I have never had a barrel "jump out" or otherwise give me any excitement. It works just as well as the Clymer fixture that we have at school. Main tube is 1" steel tubing. Bearings came from Dixie Bearing (Bearing Distributors now?), and I lathe turned the centers out of Delrin.

Bill Jacobs

What type/style belt sander you all using with these spinners? The belt sander we picked up "my dad and myself" is a hard back belt sander, and a good friend of mine says it probably wont work to well. I can see what he means.

we bought the new sander for 100 bucks and dad will use the heck out of it, as he builds hot rods for a hobby/living. now retired. Ill give this sander a try, but I may end up buying myself a small 1" belt, free standing type sander just for barrel work. maybe a 2" belt. whatever I can find. lee

we bought the new sander for 100 bucks and dad will use the heck out of it, as he builds hot rods for a hobby/living. now retired. Ill give this sander a try, but I may end up buying myself a small 1" belt, free standing type sander just for barrel work. maybe a 2" belt. whatever I can find. lee

Jay Cutright

New member

I have just about give up on polishing barrels on my lathe. I cover the ways all up and use WD-40 and wet sand paper and can get a decent lookin finish in a few minutes on most barrels. There are times though when a barrel just will not shine no matter how fast I spin it or what grit of paper I use and some barrels come from the contouring lathe so rough it's really not worth the time and trouble it takes to make it shine. (I've started with a file on some of them!)IMO, these between-centers barrel spinners are a great way to prepare lunch...if you like to eat barrels!!

I kicked around the notion of a wood lathe and a crank shaft polisher for a while and even took a barrel to a crankshaft shop and paid them to polish one for me so I could see the results. They told me $20.00 would do it and then said they'd never do another one that cheap. I took it home and finished it in my lathe with wet 320 grit and WD-40 at 1400 rpm, looked like chrome in 5 minutes.

You always have a safe way to do things and often give your opinions based on the safest way so how would you do it Jerry?

JerrySharrett

Senile Member

You always have a safe way to do things and often give your opinions based on the safest way so how would you do it Jerry?

Me? I don't polish barrels. Just using barrels to shoot benchrest, polishing adds no value besides the brands of barrels I use are slick enough.

I have, on a few hunting barrels, vapor blasted them...looks pretty sharp and doesn't reflect light.

Were I to need to polish a barrel. I would cover the lathe very thoroughly and do it there. I just have a concern about a free-spinning barrel

especially between plastic centers or on a setup where the mechanism that supports centers could flex.

Dave Tooley

Active member

Jay

Use Scotch Brite/Norton pads for the last two steps. I use a maroon colored pad after 240 grit paper then a grey pad for the final polish. Then I hose it down with WD-40 before I touch it. No finger prints this way.

Use Scotch Brite/Norton pads for the last two steps. I use a maroon colored pad after 240 grit paper then a grey pad for the final polish. Then I hose it down with WD-40 before I touch it. No finger prints this way.

Jay Cutright

New member

Thanks DaveJay

Use Scotch Brite/Norton pads for the last two steps. I use a maroon colored pad after 240 grit paper then a grey pad for the final polish. Then I hose it down with WD-40 before I touch it. No finger prints this way.

I've never tried the Grey pads I'll pick some up. The whole polishing deal makes me laugh when I think about the circle I have gone around since I started shooting custom rifles. I wanted them all to look like chrome. I had a mess of barrels needing chambered and the smith I used that year said bring em down we'll get on em and knock em out over the weekend. His helper came down sick and I spent a long 3 days polishing barrels while he was chambering. Started thinkin it wasn't all that important.

I bought my lathe and began to appreciate barrel makers like Brux and Benchmark that send out a blank presentable enough to use right out of the "sealed" plastic sleave they ship blanks in.

Now I'm back to wanting the rough barrels polished because I know it's important to some shooters, especially the new shooter with his first custom rifle and to those that walk down the firing line at a match and see a shiny rifle when they are thinking about what gunsmith to hire for their next new barrel.

It looks good! And if I'm winning with that shiny rifle it looks even better.

Problem I got with it is, I have seen or heard about to many accidents up here around the farms from people getting wound up on PTO shafts. Grabbing ahold of a barrel turning in a lathe is just like grabbing ahold of a unguarded pto shaft. I was shown a pto shaft when I was just big enough to walk and taught not to touch it.

I'll still try to get away with leaving the best blanks as they come out of the box but for the rough ones and the shooters that just gotta have em shiny I'm gonna keep lookn for a better way to do it right and do it fast without losing any teeth. (Or Limbs!)

Jay

Last edited: