F

Fla mac

Guest

Anyone,

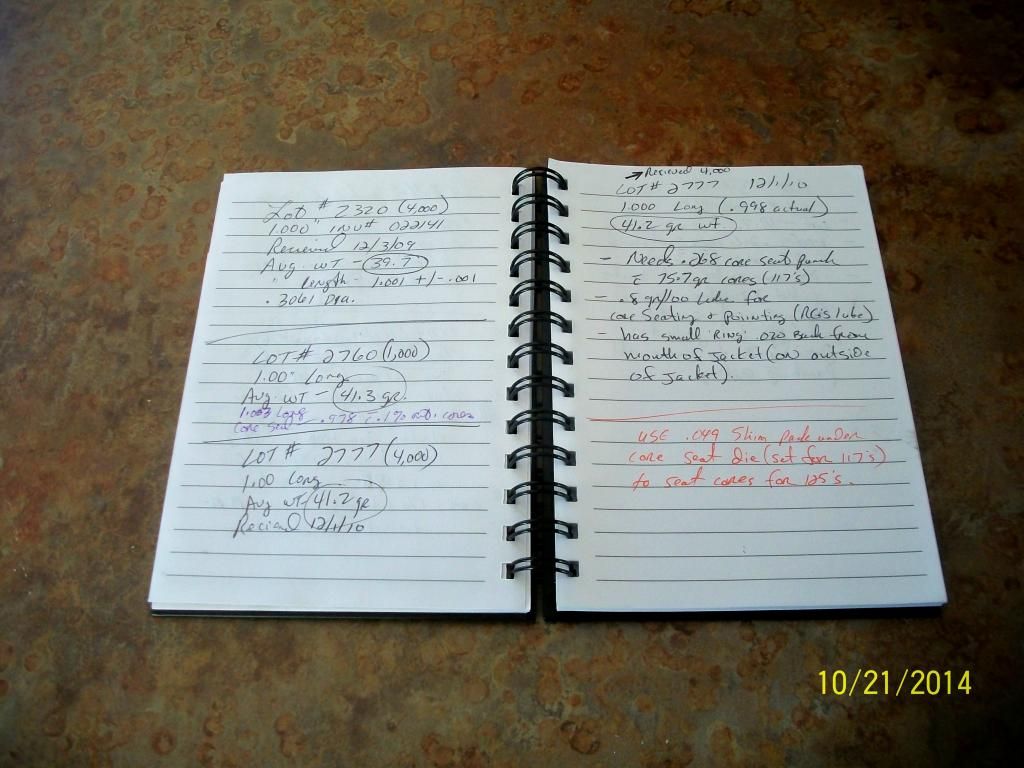

I have been making 30 cal. bullets with a set of Blackmon dies for about 5 or 6 years. This is my question has anyone been able to lube your jackets before seating the cores and pointing your bullets by thumbing them. When I seat my cores I use an ink pad and roll the jackets to apply the lube. When I point my seated jackets I apply lube to my thumb and first two fingers and roll the seated jacket between my fingers. The problem with applying the lube this way is you get variations in the ogive to base length. After making the bullets I clean them with a towel, check them for ogive length and sort them by length. Is there any way to get away from the variations in the ogive length?

john

Mims, Fl.

I have been making 30 cal. bullets with a set of Blackmon dies for about 5 or 6 years. This is my question has anyone been able to lube your jackets before seating the cores and pointing your bullets by thumbing them. When I seat my cores I use an ink pad and roll the jackets to apply the lube. When I point my seated jackets I apply lube to my thumb and first two fingers and roll the seated jacket between my fingers. The problem with applying the lube this way is you get variations in the ogive to base length. After making the bullets I clean them with a towel, check them for ogive length and sort them by length. Is there any way to get away from the variations in the ogive length?

john

Mims, Fl.