I found that;

Montana Extreme will eat a metal Ronsonol can. I'm in a constant search for solvent handling methods, literally hundreds of containers. I've found some decent methods but the metal flip-spout Ronsonol can just flunked

I found that;

Boattails hanging down into the powder chamber a long way don't necessarily hurt accuracy.

I do this a lot but have never on Match stuff. Today I was in a hurry. I had re-chambered a barrel for my Heavy gun using a 300WSM reamer with .000 freebore and wanted to try some Berger 230gr......and didn't want to take the time to throat for them..... here's a pic

These hang 'WAYYYY down! But they shot good enough that I slobbered together a box of Match loads with them just in case I don't get time to throat it "right"

I learned a new way to take pix thru my scope

I'm lazy, I'm always short for time and I live on the range..... so I rarely go down and re-hang nor collect targets. I shoot enough, and fast enough shooting right out the window that I'll roll another gun into rotation rather than let one cool. I generally have at least 3 in rotation anyway. I shoot on blueprint paper and often test many guns on one sheet of paper. I document with sketches and if I'm running out of light I'll shoot a phone pic thru the scope. And it's ALWAYS a pita.

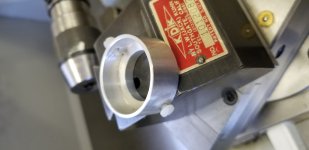

But today I got smart. I ran out on the chopsaw and cut a hunk of pipe. It took me two tries to get it right. It makes documentation easy and I was proud enough to take a pic of me taking a pic...... here's a pic

And lastly...... this one is 'YUGE for me. I screwed up a resizing die and maybe stumbled into something good.

I say MAYBE, fingers crossed.

I'm a fitted die FREAK..... so much so that I insist on selling guns, even hunting guns ONLY with fitted dies. I truly believe that NO RIFLE of any sort can possibly shoot to anywhere near it's potential without perfectly fitted ammunition. I've tried every avenue available for over 20yrs trying to solve this conundrum easily and repeatably. I've recently experimented with re-cutting factory dies to fit my chambers. Factory dies are always too small and I purposely build my chambers over-sized so re-cutting dies makes sense if I need a die quick (Whidden is several months out for instance)

So I bought a boatload of Redding Type S full length sizers, the ones that take neck bushings and started whittling. The first one I started my cut at the shoulder too far in and buggered the neck/shoulder junction. I look into the die and I can see a flat ring instead of a blend where the shoulder meets the body.

But I got the other dimensions OK, and I'd paid 90 bucks for the die so what-the-hey, "let's try 'er out!"

It actually leaves a step in the shoulder when it sizes....... But I sized and fired a round of cases 6 times, fired them HOT, repeatedly....... and they fell into the chamber with no bolt resistance and after the 5th sizing the cases had not grown at all.....

NONE

They were LOCKED from sliding by that wee step and they re-sized perfectly over and over! Now, until I've loaded these cases 30-40-50 times I won't KNOW, but I'm fairly certain this can work

here's a pic showing the resultant ring at the junction.

At this point my assertion is "that step's not a MISTAKE, that's a FEATURE!"

LOL

There was more but I'm tired and this site won't take some of the pic files.... so anyways, good day here since't I couldn't be AT a match, at least I got one gun tuned up for the next one

al

Montana Extreme will eat a metal Ronsonol can. I'm in a constant search for solvent handling methods, literally hundreds of containers. I've found some decent methods but the metal flip-spout Ronsonol can just flunked

I found that;

Boattails hanging down into the powder chamber a long way don't necessarily hurt accuracy.

I do this a lot but have never on Match stuff. Today I was in a hurry. I had re-chambered a barrel for my Heavy gun using a 300WSM reamer with .000 freebore and wanted to try some Berger 230gr......and didn't want to take the time to throat for them..... here's a pic

These hang 'WAYYYY down! But they shot good enough that I slobbered together a box of Match loads with them just in case I don't get time to throat it "right"

I learned a new way to take pix thru my scope

I'm lazy, I'm always short for time and I live on the range..... so I rarely go down and re-hang nor collect targets. I shoot enough, and fast enough shooting right out the window that I'll roll another gun into rotation rather than let one cool. I generally have at least 3 in rotation anyway. I shoot on blueprint paper and often test many guns on one sheet of paper. I document with sketches and if I'm running out of light I'll shoot a phone pic thru the scope. And it's ALWAYS a pita.

But today I got smart. I ran out on the chopsaw and cut a hunk of pipe. It took me two tries to get it right. It makes documentation easy and I was proud enough to take a pic of me taking a pic...... here's a pic

And lastly...... this one is 'YUGE for me. I screwed up a resizing die and maybe stumbled into something good.

I say MAYBE, fingers crossed.

I'm a fitted die FREAK..... so much so that I insist on selling guns, even hunting guns ONLY with fitted dies. I truly believe that NO RIFLE of any sort can possibly shoot to anywhere near it's potential without perfectly fitted ammunition. I've tried every avenue available for over 20yrs trying to solve this conundrum easily and repeatably. I've recently experimented with re-cutting factory dies to fit my chambers. Factory dies are always too small and I purposely build my chambers over-sized so re-cutting dies makes sense if I need a die quick (Whidden is several months out for instance)

So I bought a boatload of Redding Type S full length sizers, the ones that take neck bushings and started whittling. The first one I started my cut at the shoulder too far in and buggered the neck/shoulder junction. I look into the die and I can see a flat ring instead of a blend where the shoulder meets the body.

But I got the other dimensions OK, and I'd paid 90 bucks for the die so what-the-hey, "let's try 'er out!"

It actually leaves a step in the shoulder when it sizes....... But I sized and fired a round of cases 6 times, fired them HOT, repeatedly....... and they fell into the chamber with no bolt resistance and after the 5th sizing the cases had not grown at all.....

NONE

They were LOCKED from sliding by that wee step and they re-sized perfectly over and over! Now, until I've loaded these cases 30-40-50 times I won't KNOW, but I'm fairly certain this can work

here's a pic showing the resultant ring at the junction.

At this point my assertion is "that step's not a MISTAKE, that's a FEATURE!"

LOL

There was more but I'm tired and this site won't take some of the pic files.... so anyways, good day here since't I couldn't be AT a match, at least I got one gun tuned up for the next one

al