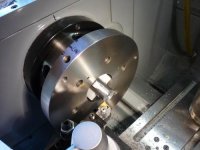

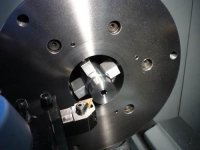

I'm looking for some 3/8-24 swivel pad set screws for my spider chuck. I have 3/8-24 brass tipped screws now that have been working fine up till now. I had a customer bring a barrel in, When I chucked it up to get enough to thread and chamber my screws are on the taper of the barrel. I only have about 30% contact on the brass tips. I thought some of these screws might solve the problem. I have looked all over web and all I can find is 3/8-16

Thanks Boe

Thanks Boe

Last edited: