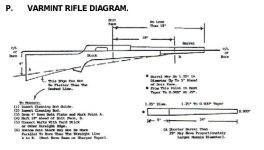

I have a question concerning the NBRSA varmint stock diagram. While there is no mistaking that you drop down 4" below the bore centerline by inserting a cleaning rod and bore guide to mark point "A". My concern is point "B". Mark the barrel 18" in front of the bolt face. Lets say you put a wrap of masking tape. The thing is this. It does not say that the height of point "B" is the bore centerline, and furthermore, the diagram shows the line from the butt of the stock intersecting point "B" on the underneath side of the barrel, not at the bore centerline. This would put point "B" down from the bore centerline by .530" based on the HV barrel taper. This would allow the bottom of the butt to have a slower taper than if the intersection was at the bore centerline. If I were to build a stock based on the drawing, and someone said the taper was too slow based on point "B" being a bore centerline measurement, it seems to me that it could be protested according to the drawing. I do realize that point "A" being based on 4" down from bore centerline could not be protested. Before anyone jumps to any conclusions, please understand that I do understand how to read a blueprint. Maybe a better explanation of this drawing lies elsewhere with a better description or better drawing.

Just to let you know, my CAD drawing shows the two angles to be 5.45 degree to the bottom of the barrel versus 6.27 degrees to the bore centerline. So it makes less than 1 degree difference, but I just want slower angle, and I don't want anyone to tell me it's not legal after I've done it. What it really comes down to is the drawing is either right or wrong. That's all I need to know.

Michael

Just to let you know, my CAD drawing shows the two angles to be 5.45 degree to the bottom of the barrel versus 6.27 degrees to the bore centerline. So it makes less than 1 degree difference, but I just want slower angle, and I don't want anyone to tell me it's not legal after I've done it. What it really comes down to is the drawing is either right or wrong. That's all I need to know.

Michael

Last edited: