Here we go...I took some photos and put them in TinyPics.com...I will paste them in and see how it turns out...

Here is the basic concept;

Using a quality ribbed/corrigated type anti-vibration pad about 4"x4"..(bought it on Ebay) and some SuperFeet...(only thing I had in the shop that was neoprene faced)...I installed the AV material between the motor mount/bracket and the lathe frame.

I removed and replaced the hard washers on the 3 mounting bolts with the superfeet...and adjusted motor belt tension to the minimum that would still pull without slipping...isolating the harmonic "buzz' coming from the motor..

Grizzly mounts the motor on rubber/polyurethane pads..but they are too hard to absorb the vibration...It is IMPERATIVE that the anti-vibration pad and the soft washers NOT be compressed...use light torque on the bolts (about 20-30 ft.lbs)...the motor will not slip or move when it is turned on-off or run at high speed...let the AV material absorb the vibration...if you over tighten or compress the material you will defeat its purpose...

Photo of the lathe motor mount with AV material in place...

Photo of factory installed rubber pad...way too hard to do any good..!

Photo of anti-vibration material and superfeet used...

Make sure you remove these hard washers and use a soft face washer or you will be tempted to over torque the mounting bolts

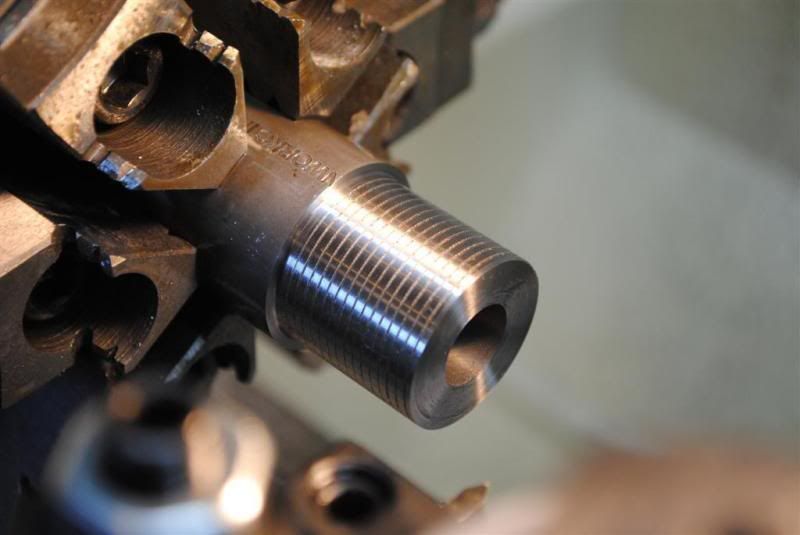

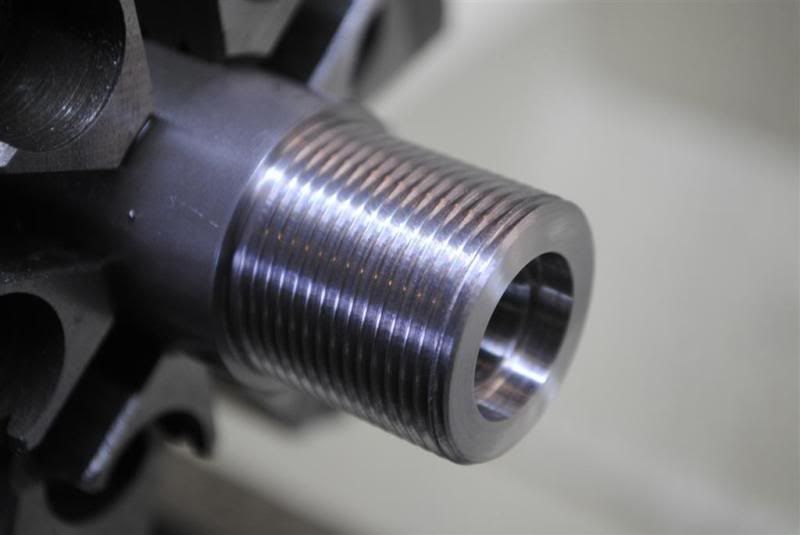

Thread with chatter before the "fix"

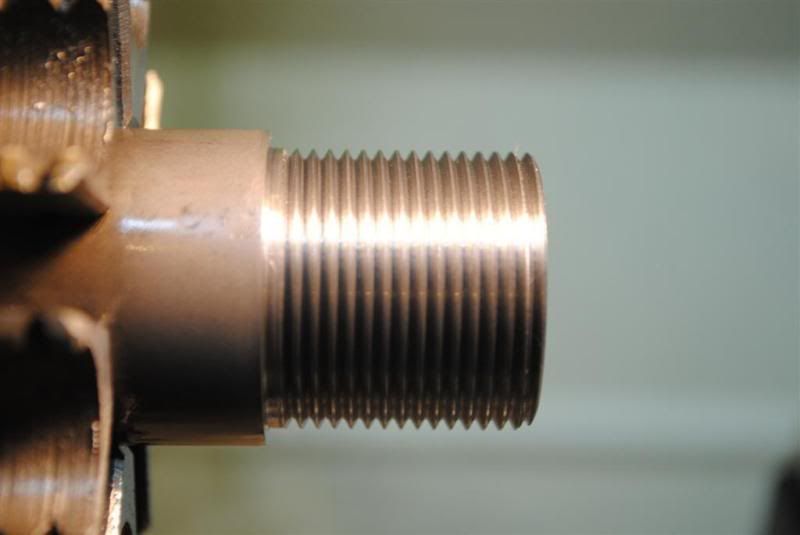

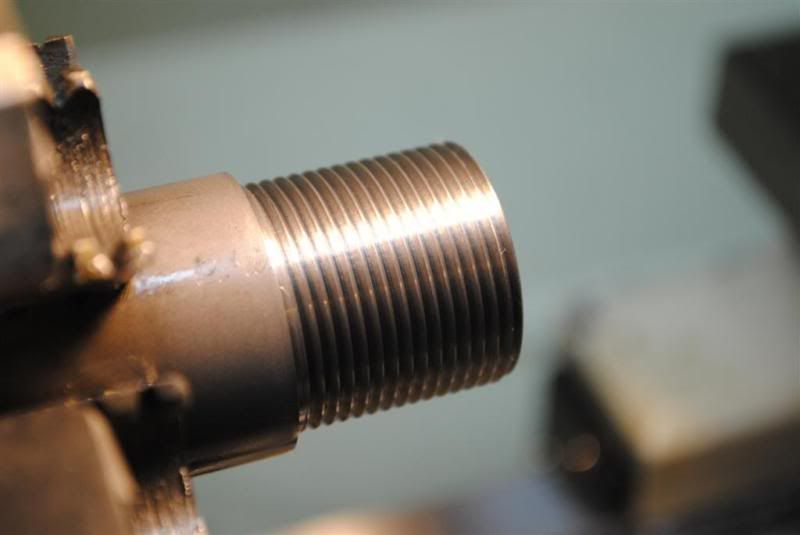

Before and after results of threads cut at 70 rpm with a CARBIDE threading tool...

Hope this is of help to others...if there is something I missed...let me know...

my lathe is much quieter now and is making threads like it was supposed to...

Eddie in Texas