Hi all,After 5 years i finally got around to testing the gun with and without the stretcher..I have a load for club matchs that i pulled from hat 2 years ago using 200Smks in a 13 twist,shoots good but not great (still took SG at 600yds recently in heavy mirage).. Anyway ,results without is vertical dispersion was approx 4 times more and overall group size was 3 times bigger,small test ,but it was obvious that a load that would shoot good in tensioned form turned to mush without ..JR..Jeff Rogers..ps .this load was never actually tuned for either form,just guessed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tensioned Barrel Tests!

- Thread starter a.JR

- Start date

I too am an afficianado of tension-barrels, but haven't had quite the success of Jeff. I have had a couple that won a lot of relays, but also a couple that didn't perform that well.

As to performance, I think a tensioning tube will bring out the best a barrel has to offer, but an average barrel just won't be turned into a great barrel just by adding atube; anyone shooting a great barrel will still beat you.

Heat can be an issue. I had a 6-Ackley that would shoot 10 shots, and then begin to scatter shots a bit. Not a great deal, but enough to take you out of a win. Oddly enough, this rifle was one of those that won a lot of relays, almost every time out was a win as long as I fired no more than 5 sighters.

This tensioning tube was stainless steel, .040 wall with about 160 holes for convection cooling. I've since come around to Jeff's way of thinking; 6061 T-6 aluminum with a thicker wall is a better material for the tensioning tubes.

Me & Joel Pendergraft have tried a number of things, and the conclusion I draw is that (1) a tube won't make a bad barrel a winner, (2) we still don't have a no-fail recipe, and (3) the machining work must be on par with the other build requirements. But with a good barrel, the tensioning tube gives you a decided edge in both tuning & staying in tune.

Maybe Jeff has a recipe he'll swear by; that would be good to know.

FWIW

As to performance, I think a tensioning tube will bring out the best a barrel has to offer, but an average barrel just won't be turned into a great barrel just by adding atube; anyone shooting a great barrel will still beat you.

Heat can be an issue. I had a 6-Ackley that would shoot 10 shots, and then begin to scatter shots a bit. Not a great deal, but enough to take you out of a win. Oddly enough, this rifle was one of those that won a lot of relays, almost every time out was a win as long as I fired no more than 5 sighters.

This tensioning tube was stainless steel, .040 wall with about 160 holes for convection cooling. I've since come around to Jeff's way of thinking; 6061 T-6 aluminum with a thicker wall is a better material for the tensioning tubes.

Me & Joel Pendergraft have tried a number of things, and the conclusion I draw is that (1) a tube won't make a bad barrel a winner, (2) we still don't have a no-fail recipe, and (3) the machining work must be on par with the other build requirements. But with a good barrel, the tensioning tube gives you a decided edge in both tuning & staying in tune.

Maybe Jeff has a recipe he'll swear by; that would be good to know.

FWIW

Jeff and Charles

As someone who is currently working on making a tensioned barrel I sure do appreciate your information and any I get on tensioned tubes.

Right now my hold up is waiting on a new stock with a larger channel for the barrel for the project. I already have the muzzle threaded and the muzzle tension nut made out of 7075 T651 but I am also plan to try 416 for the nut to see if the extra weight helps or hinders. I'm waiting on the stock before I chamber and thread the barrel. Contrary to what has been successful I am trying 2024 T3 .083" wall for the tube, only because it is harder than 6061 T6.

James

As someone who is currently working on making a tensioned barrel I sure do appreciate your information and any I get on tensioned tubes.

Right now my hold up is waiting on a new stock with a larger channel for the barrel for the project. I already have the muzzle threaded and the muzzle tension nut made out of 7075 T651 but I am also plan to try 416 for the nut to see if the extra weight helps or hinders. I'm waiting on the stock before I chamber and thread the barrel. Contrary to what has been successful I am trying 2024 T3 .083" wall for the tube, only because it is harder than 6061 T6.

James

James, i have already had this discussion with Jeff about the alloy you are using.

Here in Aus, those 2000 grade alloys are regarded as free machining in most, but not all applications. The "T3" is the tensile rating of the alloy, T2 thru T7 is the standard range. When we used a 2000 grade alloy and tensile strength of less than T5, or in other words T3 or T4, this is when we encountered some problems. The alloy on tensioning distorted under load and galled badly on assembly or dis-assembly. The results of actual fire testing are long gone from my memory so i am not saying that things will fail. Our T6 alloys are structurally sounder and can take very high tensions. This brings me to the alloy nut. Alloy to alloy rarely works without one galling and the percieved tension on tightening can often be confused with a galled and locked up system that if it does become loose during the heat of firing and barrel lenghtening is a definite recipe for failure. The 416 nut IMO is the far better option, unless you have a thin steel or bronze washer between the two alloy components. As a machinist i should know this, but i don't know if the alloy and tensile ratings are the same in both our countries, so you may have an alloy that is very well suited to this application.

I don't know for sure if i am wrong or right on this but i consider a tensioned barrel to be very non reliant on anything related to harmonics like we all acknowledge with the bare barrel. This tensioning using a tube is IMO purely a structural brace that takes control of the muzzle like one does when holding a high pressure water hose. If the barrel oscillates or vibrates inside the tube, then i think it does it with both ends under some sort of control. Where i think the real advances will be made in tensioned barrels in the future will be more likely in what the profile inside the tube will be. I am reckoning it will always be a profile that the tube can control, not the other way around. This is probably why Jeff and i have had the best sucess with larger diameter tubes completely engulfing the barrel and bearing up against the action.

James i am glad to see you are going to the larger tube and opening up the barrel channel to suit.

Best of luck again and keep us all posted.

Tony Z.

Here in Aus, those 2000 grade alloys are regarded as free machining in most, but not all applications. The "T3" is the tensile rating of the alloy, T2 thru T7 is the standard range. When we used a 2000 grade alloy and tensile strength of less than T5, or in other words T3 or T4, this is when we encountered some problems. The alloy on tensioning distorted under load and galled badly on assembly or dis-assembly. The results of actual fire testing are long gone from my memory so i am not saying that things will fail. Our T6 alloys are structurally sounder and can take very high tensions. This brings me to the alloy nut. Alloy to alloy rarely works without one galling and the percieved tension on tightening can often be confused with a galled and locked up system that if it does become loose during the heat of firing and barrel lenghtening is a definite recipe for failure. The 416 nut IMO is the far better option, unless you have a thin steel or bronze washer between the two alloy components. As a machinist i should know this, but i don't know if the alloy and tensile ratings are the same in both our countries, so you may have an alloy that is very well suited to this application.

I don't know for sure if i am wrong or right on this but i consider a tensioned barrel to be very non reliant on anything related to harmonics like we all acknowledge with the bare barrel. This tensioning using a tube is IMO purely a structural brace that takes control of the muzzle like one does when holding a high pressure water hose. If the barrel oscillates or vibrates inside the tube, then i think it does it with both ends under some sort of control. Where i think the real advances will be made in tensioned barrels in the future will be more likely in what the profile inside the tube will be. I am reckoning it will always be a profile that the tube can control, not the other way around. This is probably why Jeff and i have had the best sucess with larger diameter tubes completely engulfing the barrel and bearing up against the action.

James i am glad to see you are going to the larger tube and opening up the barrel channel to suit.

Best of luck again and keep us all posted.

Tony Z.

Tony

Thank you for your guidance.

In regard to the alloy I am planning on using. I did a lot of research on the aluminum alloys before starting this project and here is what I found. I already relayed this to Jeff. All the data that I can find says the hardness and tensile strength of 2024 tempered to T3 is superior to 6061 tempered to T6. Things that I don’t know that will relate to the suitability of the 2024 are its vibration characteristics compared to 6061 and the consistency of the wall thickness of the 2024 that I am using. Either of those could make it a bad choice. I have no way to check wall thickness consistency so I will just see how it performs when I get it together. I am in no way trying to be argumentative (I may be dumb but I sure ain’t dumb enough to try to argue with a knowledgeable source who is trying to help), just giving my reasoning for choosing the alloy that I did.

Here are links to my alloy information.

2024 T3

6061 T6

2024 T6

Kaiser Aluminum

If you lookup the 2024 at Kaiser they don't list T3 but T351 would be equivalent.

I don't recall if the 2024 I have is from Kaiser or Alcoa, I know I have some aluminum from each.

In regard to the galling that is one of my concerns also, even with the 416. I am hoping that I can chill the tube with a pressurized liquid such as the cans of keyboard duster (or whatever it’s called) and tighten it just snug. Hopefully the tube will contract enough when chilled to get enough tension on the barrel so that it will maintain tension when the barrel heats up while firing. I'll just have to see if it will work out. I am not concerned with galling on removal just assembly. Also one of the reasons for trying the aluminum nut was because of the possibility of the heavy 416 nut having more of a tuner (weighted muzzle attachment) effect so I want to try both to evaluate the difference in the effect of the added weight.

Again I certainly do appreciate all the help, even if I don’t follow it exactly. I do plan on also trying the 6061 T6 but will start with what I have on hand.

James

Thank you for your guidance.

In regard to the alloy I am planning on using. I did a lot of research on the aluminum alloys before starting this project and here is what I found. I already relayed this to Jeff. All the data that I can find says the hardness and tensile strength of 2024 tempered to T3 is superior to 6061 tempered to T6. Things that I don’t know that will relate to the suitability of the 2024 are its vibration characteristics compared to 6061 and the consistency of the wall thickness of the 2024 that I am using. Either of those could make it a bad choice. I have no way to check wall thickness consistency so I will just see how it performs when I get it together. I am in no way trying to be argumentative (I may be dumb but I sure ain’t dumb enough to try to argue with a knowledgeable source who is trying to help), just giving my reasoning for choosing the alloy that I did.

Here are links to my alloy information.

2024 T3

6061 T6

2024 T6

Kaiser Aluminum

If you lookup the 2024 at Kaiser they don't list T3 but T351 would be equivalent.

I don't recall if the 2024 I have is from Kaiser or Alcoa, I know I have some aluminum from each.

In regard to the galling that is one of my concerns also, even with the 416. I am hoping that I can chill the tube with a pressurized liquid such as the cans of keyboard duster (or whatever it’s called) and tighten it just snug. Hopefully the tube will contract enough when chilled to get enough tension on the barrel so that it will maintain tension when the barrel heats up while firing. I'll just have to see if it will work out. I am not concerned with galling on removal just assembly. Also one of the reasons for trying the aluminum nut was because of the possibility of the heavy 416 nut having more of a tuner (weighted muzzle attachment) effect so I want to try both to evaluate the difference in the effect of the added weight.

Again I certainly do appreciate all the help, even if I don’t follow it exactly. I do plan on also trying the 6061 T6 but will start with what I have on hand.

James

J

J. Pendergraft

Guest

Charles and I heated a barrel one time and then tensioned the nut. That was a mistake, we got way too much tension. You can get too much tension as well as too little. Maybe cooling the tube will be just right, some of this stuff is just trial and error.

Tubes!

Hi All , I dumbed onto a successfull way of stretching the barrel and do not intend to change ,simply because of the results .. Important points to me ,action is conventionally bedded/glued(no blocks /tube stocks), action is of a size that will carry the extra weight of the tube and nut, tube is in contact with action face,the tube has contact with the barrel radially to allow good transfer of heat ,Tube size that is just large enough to control the barrel dimensions and no more . a simple threaded nut to supply tension , no other fancy engineering ..One thing i have noticed recently is that some of the devotees of the "Barrel TUNA" thing are saying that the tensioner system can supply very similar results

Hi All , I dumbed onto a successfull way of stretching the barrel and do not intend to change ,simply because of the results .. Important points to me ,action is conventionally bedded/glued(no blocks /tube stocks), action is of a size that will carry the extra weight of the tube and nut, tube is in contact with action face,the tube has contact with the barrel radially to allow good transfer of heat ,Tube size that is just large enough to control the barrel dimensions and no more . a simple threaded nut to supply tension , no other fancy engineering ..One thing i have noticed recently is that some of the devotees of the "Barrel TUNA" thing are saying that the tensioner system can supply very similar results

Attachments

Last edited:

Tony, I've tried this, a bit. My current 6mm barrel is 1.25 (straight) for about 6 inches, a 45-degree step-down to about .850, then a 45-degree step-up to 1-inch for 4 inches at the muzzle. It's a 31- or 32-inch barrel, don't remember whichWhere i think the real advances will be made in tensioned barrels in the future will be more likely in what the profile inside the tube will be. Tony Z.

It shoots well, but it has a "feature" that takes it outside Jeff's formula. It is barrel blocked on the tube, so the action & barrel make no contact with the stock. I had thought the barrel at the breech was a tight fit in the tube, but Joel, who finished it off one night after I went home, says no, the barrel is in contact with the tube for just an inch or so. I believe that's right, he can correct me if I'm wrong.

That rifle shot 3 consecutive 5-shot groups into a flat .2 aggregate at 100 yards, using the 106-grain Clinch River bullets. It also got me a top-20 (group) at the 2006 IBS Nats. It was very windy at the Nats, and I was unwilling to give up on the 2-gun score + group on day 1, so in an attempt to keep my score up, I was holding off all over the white. Foolish of me. Regan Green, who won HG group, shot a 55 (out of 100) score day 1, but a real small group. You gotta learn to take what is there.

This is a little six; I can't really bring myself to think of it as anything more than a 600 yard gun if the wind is up. But man, will it shoot.

I think the barrel profile is a good testing point; I got the idea from Dave Tooley, who remarked that silhouette taper barrels often shoot better than other common profiles.

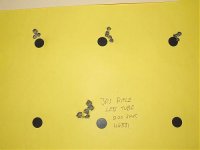

Hi All , I dumbed onto a successfull way of stretching the barrel and do not intend to change ,simply because of the results .. Important points to me ,action is conventionally bedded/glued(no blocks /tube stocks), action is of a size that will carry the extra weight of the tube and nut, tube is in contact with action face,the tube has contact with the barrel radially to allow good transfer of heat ,Tube size that is just large enough to control the barrel dimensions and no more . a simple threaded nut to supply tension , no other fancy engineering ..One thing i have noticed recently is that some of the devotees of the "Barrel TUNA" thing are saying that the tensioner system can supply very similar results , mabye so ,but 1 thing i know for sure is if you shoot 2 different loads at say at 500yds then the low pressure one will arrive at a lower point on the paper than the high pressure ..It does not converge to the same point ..Included is a pic of a test that i did at 551yds (forget the group on the far left,test bullets).. the one in the middle is 73.5 gns ,the one on the left is 75.5 gns and on the right is 77.5 gns ..Please note that each group is progressively higher up the paper ,but the vertical dispersion changes from only .900ins to 1.100ins .. If anything has become obvious to me is that you can have the weather change from 75f at 30% hum at the start of the competition weekend and rise to 100f at 95% hum during and the gun will still shoot good groups..JR..Jeff Rogers

Jeff

I was a little interested in tensioned barrels so a while back I posted an inquiry about them, you replied and posted that photo and that is when I got a lot interested in tensioned barrels.

My thinking is if I can make this work all I need to do is pick the load with the lowest velocity ES for best results.

James

Charles, the weekend just gone where Jeff did his test of with and without the tube fitted, i was also there with a LV in 6BR fitted with a tube that had a slender barrel profile inside. I went with a 67 grain bullet i was given as a sample pack, a 30 grain charge of a powder i had never used in a 6BR. Jeff shot at 200 yards as did i, my first group clustered into a .350. That was 10 thou into the lands and the next group shot a vertical slot of .690 when the pills were 10 thou out. Went back to 10 thou in and it repeated with a .357 five shotter. Now this is nothing special for a LV, but you normally have to do some sort of tuning to go in this area, no matter what barrel or bullet or powder you are using in either a 6BR or 6 PPC. Maybe i was just plain lucky? Now i have to get to a registered match and see how things go. Money where the mouth has been for quite a while now.

Put simply, the tubes work, and when they work they are a thing of joy just as you have decribed in your last post. The suprise to me is that for the small, and i do mean small, amount of people that have played (persevered, not perfected) with tubes are saying very similar things. It suprises me that the Tuna is now creating huge interest in Centrefire BR in the US, yet the tube guns are still the poor cousin. I have played with both and my mind is made up as to which is the most reliable over the ENTIRE life of the barrel.

James, thanks a bunch on that info. I will be doing some investigating on what we can get over here. This is, by the data shown, a very superior alloy in most every department over the current alloy we have been using. My memory seems to say that Stolle uses this same 2024 alloy for their action bodies. This thread has become a very good source of information.

Tony Z.

Put simply, the tubes work, and when they work they are a thing of joy just as you have decribed in your last post. The suprise to me is that for the small, and i do mean small, amount of people that have played (persevered, not perfected) with tubes are saying very similar things. It suprises me that the Tuna is now creating huge interest in Centrefire BR in the US, yet the tube guns are still the poor cousin. I have played with both and my mind is made up as to which is the most reliable over the ENTIRE life of the barrel.

James, thanks a bunch on that info. I will be doing some investigating on what we can get over here. This is, by the data shown, a very superior alloy in most every department over the current alloy we have been using. My memory seems to say that Stolle uses this same 2024 alloy for their action bodies. This thread has become a very good source of information.

Tony Z.

Tony

I would also look at 7075 T6 or 7068 T6 if you can find it in tube. The Kaiser website lists both under tube so they must make it, finding it is another matter though.

I was unable to find either in tube but did find 7075 T651 in round rod so because of it's hardness that is what I used as a nut, as I said earlier I will also try 416 for the nut.

Getting back to the reasons you are currently using 6061 T6, if wall thickness isn't consistant or the vibration qualities are poorer for this purpose with the other alloys, the 6061 T6 may still be a better choice.

James

I would also look at 7075 T6 or 7068 T6 if you can find it in tube. The Kaiser website lists both under tube so they must make it, finding it is another matter though.

I was unable to find either in tube but did find 7075 T651 in round rod so because of it's hardness that is what I used as a nut, as I said earlier I will also try 416 for the nut.

Getting back to the reasons you are currently using 6061 T6, if wall thickness isn't consistant or the vibration qualities are poorer for this purpose with the other alloys, the 6061 T6 may still be a better choice.

James

These are some photos of what we use for tubing and fittings for some of our HGs aswell as the target shot by Jeff and myself over the weekend. The group of Jeff's rifle with the tube fitted is not in my keeping. He has that. The last photo shows the 6BR and some of the different types of Tunas i have toyed with over years past.

Lynn, as you can see there is not a lot in what we are using and the barrels set up with their tubes fitted, weigh all up less than a 22 inch LV profile barrel. The difference is that you do not have the tuner weight fixed to the muzzle, and if Calfee is right about stopped muzzles and slender barrel profiles, this could be 12 to 18 ounces which is going to have a LV very nose dominant.

The barrel profile inside the tube of the 6BR pictured is 23 inches in length to the bolt face, 800 thou at the muzzle then tapering like a Palma profile to 1 3/32 inch at the chamber. Barrel tennon is 1" x 16 TPI which leaves a small shoulder for abuttment. This profile allows an outer tube diameter of 1 1/4" and the inside just cleaned up a little to allow the chamber end to fit neatly inside. Like i said earlier, the profile of the barrel is such that the tube controls things at the muzzle, so a full LV profile barrel is not warranted or desired.

There is nothing but clean air inside the fitted tube, no liquids, powders, resins etc, nothing. If a machinist could not produce these parts, including a neat and proper barrel threading ready to fit, in about three hours, he should not be a machinist. So the cost of tubes fitted to barrels as you have mentioned leaves me a little bewildered.

Tony Z.

Lynn, as you can see there is not a lot in what we are using and the barrels set up with their tubes fitted, weigh all up less than a 22 inch LV profile barrel. The difference is that you do not have the tuner weight fixed to the muzzle, and if Calfee is right about stopped muzzles and slender barrel profiles, this could be 12 to 18 ounces which is going to have a LV very nose dominant.

The barrel profile inside the tube of the 6BR pictured is 23 inches in length to the bolt face, 800 thou at the muzzle then tapering like a Palma profile to 1 3/32 inch at the chamber. Barrel tennon is 1" x 16 TPI which leaves a small shoulder for abuttment. This profile allows an outer tube diameter of 1 1/4" and the inside just cleaned up a little to allow the chamber end to fit neatly inside. Like i said earlier, the profile of the barrel is such that the tube controls things at the muzzle, so a full LV profile barrel is not warranted or desired.

There is nothing but clean air inside the fitted tube, no liquids, powders, resins etc, nothing. If a machinist could not produce these parts, including a neat and proper barrel threading ready to fit, in about three hours, he should not be a machinist. So the cost of tubes fitted to barrels as you have mentioned leaves me a little bewildered.

Tony Z.

Attachments

Last edited:

Tony,

I think Lynn is talking about a 1K heavy gun. I had a more or less conventional tubed gun when Allan Peake & Stuart Elliot were over for the Super Shoot & came to Hawks Ridge -- forget the year, but Allan shot my guns, including the tubed HG. It was a big 30, & he was one relay after me, so we poured water down the barrel to cool it after the 20 shots you fire in a relay.

This one was similar to Jeff's. Later, we began to use large diameter tubes & skipped the stocks. I believe Charles Bailey was the first to take this approach. Me & Joel Pendergraft also built these kind of rifles. With the coolant inside the tube, you could fire as many rounds as you wanted & heat was never an issue. There use to be a picture of Joel's rifle on 6mmBR.com, but I think it is gone now. The cost, if you did your own work, was probably equivalent to a conventional rifle, because you could skip the stock. I think this is what Lynn had built.

If a front nut costs the price of a BAT action, means you had it made about 10 times -- anything costs if you do it ten times.

My 1K LGs are more along the line you are showing. I used 1.375 o.d. tubing. If you don't have a wooden stock, I suppose it could cost to open up the barrel channel. If you make your own stock, easy enough to open it a bit more & use 1.5-inch o.d. tubing -- that's what Joel did.

Barrels were cheap -- we just used Palma-countour barrels. I now think a sort-of-silhouette profile is a better notion. These 1K light guns -- esp. in something like a .300Ackley -- did get hot, and would scatter shots a bit after 10-12 rounds. This with ss tubes.

When I did the 6 PPC tubed gun, I used a "water jacket" based on those experiences. I now know it isn't needed -- much less heat with a PPC, and better heat transfer with aluminum tubing.

But for light guns, or for that matter, anything conventional & using a stock, cost was never a factor.

I think Lynn is talking about a 1K heavy gun. I had a more or less conventional tubed gun when Allan Peake & Stuart Elliot were over for the Super Shoot & came to Hawks Ridge -- forget the year, but Allan shot my guns, including the tubed HG. It was a big 30, & he was one relay after me, so we poured water down the barrel to cool it after the 20 shots you fire in a relay.

This one was similar to Jeff's. Later, we began to use large diameter tubes & skipped the stocks. I believe Charles Bailey was the first to take this approach. Me & Joel Pendergraft also built these kind of rifles. With the coolant inside the tube, you could fire as many rounds as you wanted & heat was never an issue. There use to be a picture of Joel's rifle on 6mmBR.com, but I think it is gone now. The cost, if you did your own work, was probably equivalent to a conventional rifle, because you could skip the stock. I think this is what Lynn had built.

If a front nut costs the price of a BAT action, means you had it made about 10 times -- anything costs if you do it ten times.

My 1K LGs are more along the line you are showing. I used 1.375 o.d. tubing. If you don't have a wooden stock, I suppose it could cost to open up the barrel channel. If you make your own stock, easy enough to open it a bit more & use 1.5-inch o.d. tubing -- that's what Joel did.

Barrels were cheap -- we just used Palma-countour barrels. I now think a sort-of-silhouette profile is a better notion. These 1K light guns -- esp. in something like a .300Ackley -- did get hot, and would scatter shots a bit after 10-12 rounds. This with ss tubes.

When I did the 6 PPC tubed gun, I used a "water jacket" based on those experiences. I now know it isn't needed -- much less heat with a PPC, and better heat transfer with aluminum tubing.

But for light guns, or for that matter, anything conventional & using a stock, cost was never a factor.

Last edited:

Tony Z

Tony alot of our older posters are not in touch with todays pricing especially in California.10 hours of machine time out here is the price of a BAT action and a 5 inch round piece of stainless even then was $150 as we pay by the pound.

If your buddy wants to make you something in his spare time that is great but if you spend a couple days going over it with a job shop you have to pay the piper out here.

Lynn

If a front nut costs the price of a BAT action, means you had it made about 10 times -- anything costs if you do it ten times.

Tony alot of our older posters are not in touch with todays pricing especially in California.10 hours of machine time out here is the price of a BAT action and a 5 inch round piece of stainless even then was $150 as we pay by the pound.

If your buddy wants to make you something in his spare time that is great but if you spend a couple days going over it with a job shop you have to pay the piper out here.

Lynn

Charles, the first three photos are of HG fittings both Jeff and i use. It may not show it, but the fitings are 2" in diameter for stretching 1 1/2 inch barrels tapering off to about 1 1/4 inch. The cost of the component material may vary a little, but the time to make them for any class gun is similar. We are obviously lucky that we do it all ourselves and do not have to go through my engineering shop paying an hourly rate.

Tony Z.

Tony Z.