I have a Farley that I bought around 2002/2003 that I need to disassemble, clean, upgrade and reassemble.

I’ve done the advanced search and saw the response that Butch gives to get most of the above done.

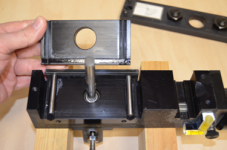

But I would appreciate it if someone could give me advice on the first couple steps on disassembling this little black box. I see three sets of screws on the top (marked A, B and C). If someone could shed some light on which to disassemble first I would greatly appreciate it. Attached are the recommendations from Butch.

• The first thing to do is disassemble the rest top thoroughly, clean and put teflon or UHMW tape on the front of the front sliding plate. The front sliding plate bears or rubs on the main rest housing.

• I like synthetic racing bicycle wheel bearing grease. Apply the grease to the front sliding plate.

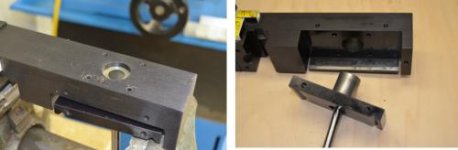

• The older Farley's had 2 square .250 keys that worked between the 2 sliding plates. Replace the keys with 2 round .250 pins. Be sure to lube the pins. Replace the tension screws with the Shadetree Engineering screws.

• Lube the buttons with the above mentioned grease. You need to also lube the adjustable plate that bolts to the bottom of the res top that slides in the back sliding plate.

• I don't remove the boot but I do take the screws out and let it float. The easiest way to adjust the tension screws for me is to set a 10lbs. weight on the bag plate and vigorously operate the stick slowly tightening the tension screws. When the screws are tight enough to hold the 10lbs. weight it will then easily hold a 17lbs rifle.

Thanks, Bill.

I’ve done the advanced search and saw the response that Butch gives to get most of the above done.

But I would appreciate it if someone could give me advice on the first couple steps on disassembling this little black box. I see three sets of screws on the top (marked A, B and C). If someone could shed some light on which to disassemble first I would greatly appreciate it. Attached are the recommendations from Butch.

• The first thing to do is disassemble the rest top thoroughly, clean and put teflon or UHMW tape on the front of the front sliding plate. The front sliding plate bears or rubs on the main rest housing.

• I like synthetic racing bicycle wheel bearing grease. Apply the grease to the front sliding plate.

• The older Farley's had 2 square .250 keys that worked between the 2 sliding plates. Replace the keys with 2 round .250 pins. Be sure to lube the pins. Replace the tension screws with the Shadetree Engineering screws.

• Lube the buttons with the above mentioned grease. You need to also lube the adjustable plate that bolts to the bottom of the res top that slides in the back sliding plate.

• I don't remove the boot but I do take the screws out and let it float. The easiest way to adjust the tension screws for me is to set a 10lbs. weight on the bag plate and vigorously operate the stick slowly tightening the tension screws. When the screws are tight enough to hold the 10lbs. weight it will then easily hold a 17lbs rifle.

Thanks, Bill.