Pete Wass

Well-known member

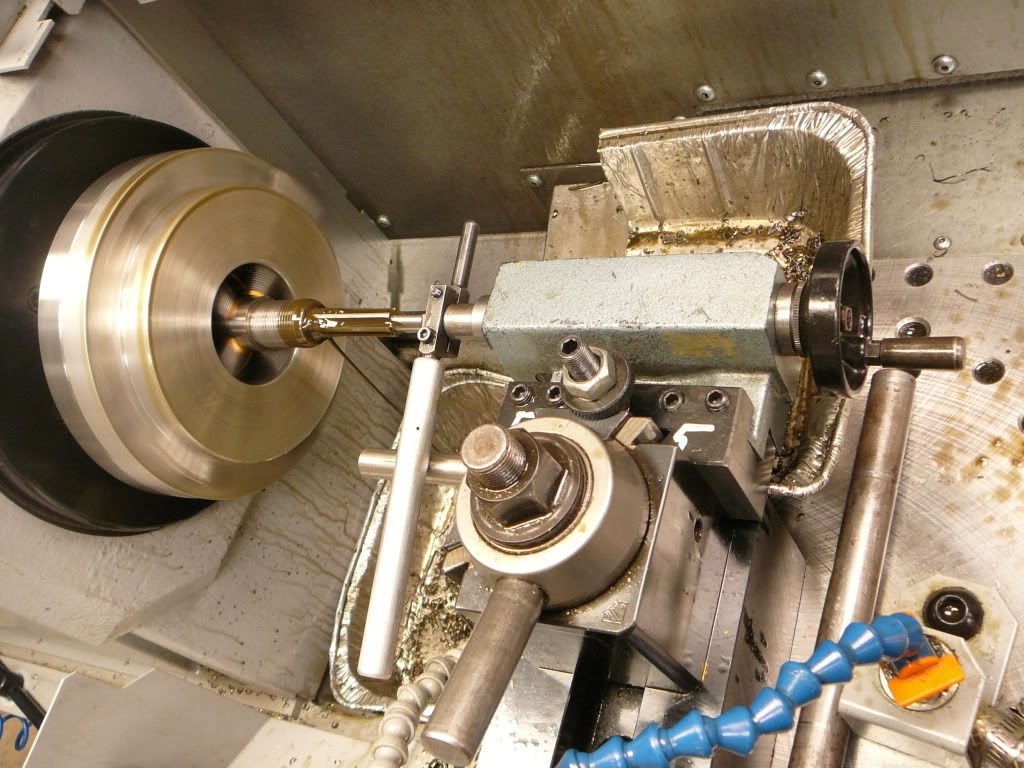

A lad, who's name I don't remember but he does a lot of surface grinding vids, did one of eliminating the compound on his lathe and substituting a block to hold his Aloris tool post rigidly, square to the bore. He has a huge number of tool holders for his tool post, including one that eliminates the tail stock. My thinking went to this reamer pushing business and if shortening the whole thing up might be helpful. I can find the vid if anyone can't and is interesting. I am thinking right now that eliminating the tailstock might be worth a bunch.

Pete

Pete