John S .......

I've always heard this part of the bullet referred to as "the point of transition" to the ogive. Like Wilbur says ... we could probably use an actual descriptive name for this transition area. However, I don't think "shoulder" will work, because that implies another surface like a semi wad cutter has.

Wilbur .......

The surface of a reamer pilot bearing rides on the inner surface of the lands (not on the groove diameter).

- Innovative

John S

Point of transition will work I guess, but your semi wadcutter statement is a fact as far as " shoulder", because it just does not apply to the ogive.

The Ogive is an arc, no shoulder. But there is a shoulder in the base of a new boat-tail design. will post a link.

But for another poster, the "Anatomy of a Bullet" is below.

Form Corbin dies, the cats meow in bullet making.

Core Swage Die : This is the die which adjusts the lead weight, and turns a piece of cut lead wire or cast lead core into a precise cylinder of the correct diameter, with flat ends. The CSW die is seldom used by itself, but is followed by the CS or PF (or both).

CS-1- Core Seat Die : This die presses the lead core into the jacket and forms the precise bullet shank. The core seater can also produce a finished jacketed semi-wadcutter bullet or lead semi-wadcutter bullet, by using a nose punch having the desired cavity shape. However, the bullet will be about 0.0002-inches undersized compared to using a LSWC or PF die.

PRO-1-R Pro-Swage : The PRO-SWAGE is a special form of the CS die which is built for use on reloading presses only, and finishes the bullet in one stroke. It is used only with soft lead and may or may not use a jacket depending on the caliber. Only SWC-style noses can be made. These are all type -R prefix since they operate in a reloading press. Example: PRO-1-R (specify caliber, nose, base shape).

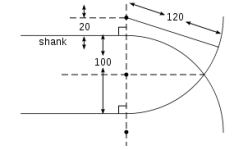

PF-1- Point Form Die : The Point Form Die or Point Former shapes the ogive curve on the bullet. If you want a bullet that does NOT have a step or shoulder between the shank and nose, you must use one of these dies to create it. Forming the nose in a punch cavity always leaves a shoulder (the edge of the punch), which we refer to as the Semi-Wadcutter shoulder. The point form die is always used with a matching CS die for jacketed bullets, and usually with a CSW die for lead bullets

LT-1- Lead Tip Die : The Lead Tip Forming die reshapes a lead tip bullet made in the point former to remove the distortion produced by ejecting the bullet from the point former die. It is never used without the PF die. The PF die comes first, then the LT die is an option if you want factory-finished lead tips, especially in sharper rifle nose shapes (many blunt or round nosed shapes look OK without using the LT die to clean them up).

RBT-2- Rebated Boattail Set : The dies to produce rebated boattails are the BT-1 and BT-2 dies. These are used as a set, INSTEAD of the usual CS die, to seat the lead core. The jacket and core are put into the BT-1 die and pressure is applied to the core with a punch, expanding the jacket and also forming a conventional angled boattail on the base. Then the assembly is ejected and put into the BT-2 die, where the angled base slides past a shoulder or rebate shape. Pressure is applied again, expanding the base section perfectly into the rebate shoulder and producing a gas sealing, muzzle blast deflecting shoulder that adds about 15% to the tightness of the group (compared to a conventional BT bullet). The RBT dies always come as a set of two, called the RBT-2.

A lot of good info from these folks

http://www.corbins.com/fjfb-3.htm