You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

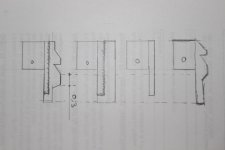

Notice anything different about this Bat M Action Bolt?

- Thread starter jackie schmidt

- Start date

C.L. Peterson

Active member

jackie schmidt

New member

Different Shroud ??

Bingo.

I have had this action for several years, it has hand numerous barrels from 6BR to 284, Winchester. The current barrel is chambered in 7 MM Geramo.

I think it has always been a shot spitter. There are some pretty astute Gunsmiths who work on the firing pin assemblies, I was ready to send it to a one who knows his way around these, but I said “what the heck”. I’ll see if I can convert it to the time tested screw in shroud.

The shroud it’s self is a Graphite impregnated piece that Gene Bukys made years ago. I have had one on both my Farley LV and HV Score Rifle for years. Thousands of rounds through both.

The Bat bolt had stock in it to bore out to accept a 1/2 13 tap. The back is bored to .500 to fit the body of the shroud.

I machine the firing pin fro a Grade 8 bolt.

The only thing I have to do now is move the trigger back, as the cocking piece that engages the trigger sear on a Remington is about .300 further back than the Bat. I will have to mill the trigger hanger slot back, and drill another tap.another 6/32 hole. I will make a custom hanger with an extended foot to catch the original forward hole.

Everything so far has come out good.

http://benchrest.com/attachment.php?attachmentid=23807&stc=1&d=1595040291

http://benchrest.com/attachment.php?attachmentid=23808&stc=1&d=1595040329

http://benchrest.com/attachment.php?attachmentid=23809&stc=1&d=1595040370

Attachments

OliveOil

Active member

The only thing I have to do now is move the trigger back, as the cocking piece that engages the trigger sear on a Remington is about .300 further back than the Bat. I will have to mill the trigger hanger slot back, and drill another tap.another 6/32 hole. I will make a custom hanger with an extended foot to catch the original forward hole.

Wouldn't that be easier to work on the cocking piece itself ?

Cut a part of the existing "wing" and weld (Ag or Cu solder ?) another one, then mill sear place and bolt-tool notch, with a little tenon/step at the front considering the effort direction.

Notice you can solder a wider, part then go to the mill, reference on the "original" cylindrical part and cut the soldered "wing" to the right width, centered and // to the axis.

With regards to milling the stock as you stated, I hope you will remains in the ?laminated?stratification? hard material. Take care, you may arrived in the foam and that would do no good if you cut the "laminated skin" where stock section is already smaller. Same goes for trigger hanger rear hole.

Olive.

Last edited:

jackie schmidt

New member

I’m not quite sure what you are referring to in milling the stock. That is a simple matter of using a pencil grinder to remove material so the newly positioned trigger hanger doesn’t hit anything.

What I will do is mill is the action it’s self. It is a simple matter of moving the rear 6/32 mounting screw back the correct amount and then milling the pad that the trigger hanger mounts on. The trigger hanger will look just like a regular Bat except for the extended mounting tang on the front pad.

As for making a cocking piece, I really don’t have the means at my disposal to make one. Plus, by the time I got it correct and had it case hardened, I could reposition the trigger.

I think I have all of the bases covered. There is nothing I hate worse than getting 98 percent through a project and realizing you hit a unsolvable roadblock.

What I will do is mill is the action it’s self. It is a simple matter of moving the rear 6/32 mounting screw back the correct amount and then milling the pad that the trigger hanger mounts on. The trigger hanger will look just like a regular Bat except for the extended mounting tang on the front pad.

As for making a cocking piece, I really don’t have the means at my disposal to make one. Plus, by the time I got it correct and had it case hardened, I could reposition the trigger.

I think I have all of the bases covered. There is nothing I hate worse than getting 98 percent through a project and realizing you hit a unsolvable roadblock.

Remington

bolt shroud and fire control innards?

bolt shroud and fire control innards?

jackie schmidt

New member

bolt shroud and fire control innards?

The shroud and firing pin is standard Remington, Panda, Farley etc. The front of the firing pin is Bat.

I finished it this morning. I moved the trigger assy back .270 inch, I came out with .220 firing pin travel and 27 pounds of static spring pressure.

Everything works great. I plan on shooting it tomorrow. One thing I noticed is when I would dry fire this rifle before, it had a real rattle. Now it is just a clean crisp snap.

http://benchrest.com/attachment.php?attachmentid=23814&stc=1&d=1595091446

http://benchrest.com/attachment.php?attachmentid=23815&stc=1&d=1595091488

Attachments

Last edited:

jackie schmidt

New member

Ed, Geramo and I had a great day at the range.

I set up at 200 yards with my standard 5 flag set Conditions were pretty tough. Lots of wind, lots of mirage.

The rifle never performed better. Loading and extraction were smooth.

We are shooting the 7MM Geramo, which is a 6.5 x 55 necked to 7mm and Ackley Improved. My bullet of choice is the 162 Hornady ELD Match. I worked with three powders, 4831 SC, Reloader 25, and H1000. Of these, the H1000 proves to be the best.

The load I settled on is 56.2 grns of H1000, Winchester primer, .020 off the lands. This gives an average velocity of 2850 FPS out of the 27 inch long Krieger.

The 7mm Geramo is turning out to be a very efficient and accurate chambering.

As I said, the Rifle never performed better. Here are three nice groups I shot, (200 yards), and five bulls eyes. I think this is an honest “250” combination.

I cannot say 100 percent that my work on this action has paid off. What I can say is the Rifle has never shot this good with any barrel I ever had on it.

This might be the Rifle that I take to the 300 meter “TackDriver” in November.

http://benchrest.com/attachment.php?attachmentid=23839&stc=1&d=1595214120

http://benchrest.com/attachment.php?attachmentid=23840&stc=1&d=1595214168

I set up at 200 yards with my standard 5 flag set Conditions were pretty tough. Lots of wind, lots of mirage.

The rifle never performed better. Loading and extraction were smooth.

We are shooting the 7MM Geramo, which is a 6.5 x 55 necked to 7mm and Ackley Improved. My bullet of choice is the 162 Hornady ELD Match. I worked with three powders, 4831 SC, Reloader 25, and H1000. Of these, the H1000 proves to be the best.

The load I settled on is 56.2 grns of H1000, Winchester primer, .020 off the lands. This gives an average velocity of 2850 FPS out of the 27 inch long Krieger.

The 7mm Geramo is turning out to be a very efficient and accurate chambering.

As I said, the Rifle never performed better. Here are three nice groups I shot, (200 yards), and five bulls eyes. I think this is an honest “250” combination.

I cannot say 100 percent that my work on this action has paid off. What I can say is the Rifle has never shot this good with any barrel I ever had on it.

This might be the Rifle that I take to the 300 meter “TackDriver” in November.

http://benchrest.com/attachment.php?attachmentid=23839&stc=1&d=1595214120

http://benchrest.com/attachment.php?attachmentid=23840&stc=1&d=1595214168

Attachments

Last edited:

jackie schmidt

New member

What is that bare aluminum sleeve near the eyepiece on your scope?

TIA,

GsT

It’s a magnifier I made from a +325 lens I bought at TSO. It turns the 36x Valdada into around 45x. I can slip it off if the need arises.

I bought a 40 tp 60 March High Master from a fellow shooter on Accurate Shooter. I should get it this week.

Gene Beggs

Active member

Jackie it's nice to see you back to your old self again, sharing your adventures and projects with us. Keep up the good work. We all appreciate it.

Best regards,

Gene Beggs

Best regards,

Gene Beggs

GeneT

Active member

It’s a magnifier I made from a +325 lens I bought at TSO. It turns the 36x Valdada into around 45x. I can slip it off if the need arises.

Slick! Thank you for the response.

GsT

jackie schmidt

New member

Jackie,Nice work. I can see it now. Your going to get a bunch of requests to convert BAT bolts to a Remington shroud lol.

It sure is easier to get a gun tuned when the firing system is working properly.

I doubt that. Most shooters will not step into something unless they are 100 percent sure they can put it back the way it was. That keeps a lot of ideas in the closet.

I figured the worst outcome I would have is buying a new Bat M bolt if this project didn’t meet expectations.

Regarding the method

BAT uses to set the firing pin fall...a screw to secure the pin in place with a second locking one, how prone is that to slippage and a change in FP fall length? Or is it bullet proof? Tks

I doubt that. Most shooters will not step into something unless they are 100 percent sure they can put it back the way it was. That keeps a lot of ideas in the closet.

I figured the worst outcome I would have is buying a new Bat M bolt if this project didn’t meet expectations.

BAT uses to set the firing pin fall...a screw to secure the pin in place with a second locking one, how prone is that to slippage and a change in FP fall length? Or is it bullet proof? Tks

I doubt that. Most shooters will not step into something unless they are 100 percent sure they can put it back the way it was. That keeps a lot of ideas in the closet.

I figured the worst outcome I would have is buying a new Bat M bolt if this project didn’t meet expectations.

Kinda a shame you have to do that for what they cost. A mere mortal might be selling an action he wasn't happy with. Makes me think twice about buying a used action without knowing it's history

This is the way I feel about it Jackie bought and paid for the action, it's his, he owns it and he can do whatever he chooses to do with it or possibly not doing anything at all. Some folks are thinkers and doer's and just about anything you buy can be improved or modified to fit ones own personal use. If not for the doers like Jackie we simply wouldn't learn anything new. Being a doer myself I thank him for sharing what it is that he does. Buy or selling to me doesn't play any part in this as he did it for himself to use not to sell.

jackie schmidt

New member

Kinda a shame you have to do that for what they cost. A mere mortal might be selling an action he wasn't happy with. Makes me think twice about buying a used action without knowing it's history

There isn’t anybody saying you got to do anything.

If I am not happy with something, I figure there are three courses of action, either just set it aside, give it away, or figure out some way to fix what I think ails it.

This just happens to be one of those times I decided to try something. Carving up a bolt and action might seem radical, but I didn’t like it the way it was, so what the heck.

I think there is a lot of miss information when it comes to things like this. I would venture that 98 percent of the custom actions sold are great right out of the box. I have never seen a Panda that didn’t shoot. That’s because Kelbly stuck with a proven system, and set it up correctly.

We used to consider the Farley as kind of an action kit. Out of the box, they had about 1/2 of the firing pin travel they needed, and not near enough spring pressure. It was not uncommon to find the threads and face were not square and true with the bolt way.

But they were darned sure worth fixing. The two best shooting rifles I have are based on ‘90’s vintage Farleys that I finally got right. The one on my 30BR has a barrel thread that is .010 over on the thread pitch diameter because it was not true. I set it up and trued the threads and face. I made a new trigger hanger In order to get 1/4 inch firing pin travel, and shimmed the spring to 25 pounds of static pressure.

Gene Bukys came up with that Graphite Impregnated Delren Shroud. Those are pure genius.

It’s a winner.

Wayne Shaw

Active member

There are a good number of smiths that make a living (in part) working over brand new actions, to make them work right.