You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My range in progress

- Thread starter skeetlee

- Start date

XBBR Shooter

New member

Lee maybe you havent noticed but having all that corn at least to a point could be a "little" like having a field full of windflags and I do mean full.

... and a lotta crows too

I'm just sayin'

Al

I do understand. I thought about a bit after reading the post and i can see were it would. The good news is that in the dead of the summer here in illinois you cant hardly buy a breeze so i am sure it will be ok. The main thing is the winter time as you said above. When its to cold to play out side, i will have a nice hang out for me and my friends to gather and tell lies. I also hope to have my lathe by the first snow, so i will have plenty to do. Lee

don't be freaked out when on one of those "you can't BUY a breeze" days you shoot goofy duck shaped groups a half inch big.......

gremlins

jeeepers y'er gonna' have fun!

al

Yes fellas it will be fun for sure. My wife probably wont like it much as the farm is about 7 miles up the road, just far enough were i wont be able to hear her nagging at me. LOL!! No actually i have a great wife and to be real honest i hear very little complaining. Notice i say, very little and not none at all. After all she is female. I am sure i will spend a lot of free time there. I will have to be careful, because the last thing i want to do is neglect family time. Balance is the key!! More pics to come after weekend progress. Lee

L

Larry Elliott

Guest

I'd like to extend my condolences to you about having your own private range, but I'm afraid a lie that big would doom me for sure - and I'm in enough trouble already.

Neat setup, hope it works well for you though!

Neat setup, hope it works well for you though!

No pics but we did get the north side steel on today. We will start with interior walls and insulation tomorrow. Something else i have been thinking about and i need some input on is the fact that two benches in my 12'x9' room is going to take up a lot of room. I am now thinking i would like to have my lathe in this room as well. What if i had one solid as heck concrete bench and one bench that would drop straight down from the left window when not in use. The idea sounds pretty good but i just dont know if i can make this bench solid enough to shoot serious groups from. My question is, how can i make a drop down, store out of the way bench that will still be adiquite(sp) to shoot benchrest from when my best shooting buddy Jim is over? Any ideas? Like i say, i am not so sure it can be done effectively. Maybe a smaller concrete bench would be best? Lee

Ok here is a pic of the window in which i may do a folding bench. Also im not sure if you can see much in this pic but i am thinking i may just use some of that blue board insulation under the sheeting so my benches can sit closer to the window edge, thus allowing the barrel to make it out the window a little easier. sound ok? Lee

You can see on the left how we used 2x4 construction and i feel that will only hinder me if i do the same on my side of the shop. Lee

You can see on the left how we used 2x4 construction and i feel that will only hinder me if i do the same on my side of the shop. Lee

Last edited:

Skeeter.......

You'll get'cher barrel out the winder no problem. This is more a function of bench design than knee-space. I've been shooting from inside for 20yrs and have set up many different situations. THAT SAID, it's entirely possible to NOT clear the windows. I've had guys lean back and SCALD the window frames. I've got powderburns on the vinyl at two stations.

Next time you're shooting bring a car door or a spare window...... well OK, you don't have to go that far ....... but set down and LOOK at yourself. Where are your knees? Where is your muzzle? If there is a conflict than maybe consider a higher stool?

....... but set down and LOOK at yourself. Where are your knees? Where is your muzzle? If there is a conflict than maybe consider a higher stool?

Anyways, I don't see where it'll be a problem. Just don't build the tails on your benches too long and no one will burn your window frames.

A free tip, worth exactly what'cha paid for it MAKE A MOCKUP! Take some old plywood sheets and mock up some tops..... fiddle with different guns/stools etc and cut/fit until you get exactly what you want before pouring the tops.

MAKE A MOCKUP! Take some old plywood sheets and mock up some tops..... fiddle with different guns/stools etc and cut/fit until you get exactly what you want before pouring the tops.

hth

al

You'll get'cher barrel out the winder no problem. This is more a function of bench design than knee-space. I've been shooting from inside for 20yrs and have set up many different situations. THAT SAID, it's entirely possible to NOT clear the windows. I've had guys lean back and SCALD the window frames. I've got powderburns on the vinyl at two stations.

Next time you're shooting bring a car door or a spare window...... well OK, you don't have to go that far

Anyways, I don't see where it'll be a problem. Just don't build the tails on your benches too long and no one will burn your window frames.

A free tip, worth exactly what'cha paid for it

hth

al

Boyd Allen

Active member

Yea, verily

Weather has been to hot to do much work, but the corn will be out in around 3 weeks so i forced my self to work on the shoot room the last couple days. I got quite a bit done. I still need to sheet the walls and insulate a bit. Here are a couple more pics of the room in progress.

You can see what i have done with the front wall. I used 1.5" foam board for the insulation, this way i can get my benches right up against the windows, and the muzzle can be outside the room. This foam board only has an R value of 7.5 so i sure hope its enough. The north wall i used 2" blue board foam plus R19 glass insulation. I built that wall with 2x4 construction. I stuffed ever nick and cranny with some loose glass insulation trying my best to seal it up. the north winds here on this farm can be quit COLD!!!

Here is an over view of the room. I built the 2x6 wall today and got all my wires ran. I think i will end up with 7 outlets in this 12x10 room. that should be plenty. I was going to sheet the walls with drywall, but i was told that i will have a moister problem and eventually a mold problem since this room wont be heated or cooled on a regulated basis. Can some one here confirm or deny this for me. If i cant use drywall i will just use OSB. I might even splurge for some paneling??

So i am getting closer. I still need some more r19 insulation and some more sheeting. I also need to re-build the concrete benches and set the block. There is something else i would like to discuss. Do i have to use mortar to set the blocks or can i use some type of liquid nails or something similar? I want the blocks strong and secure for sure!!. More pics to come when i get back to work. Tomorrow is sunday, and i have a date with a rifle so i wont be getting much work done! Enjoy! Lee

You can see what i have done with the front wall. I used 1.5" foam board for the insulation, this way i can get my benches right up against the windows, and the muzzle can be outside the room. This foam board only has an R value of 7.5 so i sure hope its enough. The north wall i used 2" blue board foam plus R19 glass insulation. I built that wall with 2x4 construction. I stuffed ever nick and cranny with some loose glass insulation trying my best to seal it up. the north winds here on this farm can be quit COLD!!!

Here is an over view of the room. I built the 2x6 wall today and got all my wires ran. I think i will end up with 7 outlets in this 12x10 room. that should be plenty. I was going to sheet the walls with drywall, but i was told that i will have a moister problem and eventually a mold problem since this room wont be heated or cooled on a regulated basis. Can some one here confirm or deny this for me. If i cant use drywall i will just use OSB. I might even splurge for some paneling??

So i am getting closer. I still need some more r19 insulation and some more sheeting. I also need to re-build the concrete benches and set the block. There is something else i would like to discuss. Do i have to use mortar to set the blocks or can i use some type of liquid nails or something similar? I want the blocks strong and secure for sure!!. More pics to come when i get back to work. Tomorrow is sunday, and i have a date with a rifle so i wont be getting much work done! Enjoy! Lee

Last edited:

liquid nails is fine, much stronger bond than mortar, but there's a better way.

You're a concrete guy, form and POUR the supports. You could do it on a jobsite and fork them into the back of your pickup but the absolute berries is to pour them right there at the shop. Here's the cool part...... look at these lifting units.

http://www.nextag.com/trailer-dolly/shop-html

maybe not these exact ones but you get the idea......

You can pour the t-shaped bases with bolt plates so's you can mount wheels on the wide end and a hook/ball/tab type receiver on the rear 't' leg and you can wheel these around with ease. When you set them down they STOP! and don't move. The wheels hang out the front so when you set it down they don't touch the floor.

You pour on visqueen and the bottom of the table support is smooth as a baby's butt, it suctions to the floor like a limpet. Now you have movable/adjustable benches you can wheel into the other room if you have a dance, or whatever.

justathought

al

You're a concrete guy, form and POUR the supports. You could do it on a jobsite and fork them into the back of your pickup but the absolute berries is to pour them right there at the shop. Here's the cool part...... look at these lifting units.

http://www.nextag.com/trailer-dolly/shop-html

maybe not these exact ones but you get the idea......

You can pour the t-shaped bases with bolt plates so's you can mount wheels on the wide end and a hook/ball/tab type receiver on the rear 't' leg and you can wheel these around with ease. When you set them down they STOP! and don't move. The wheels hang out the front so when you set it down they don't touch the floor.

You pour on visqueen and the bottom of the table support is smooth as a baby's butt, it suctions to the floor like a limpet. Now you have movable/adjustable benches you can wheel into the other room if you have a dance, or whatever.

justathought

al

Andy Cross

New member

Bench tops

I read this thread with interest. A friend in outback Oz who owns a ranch has built three bench set ups on the property primarily with 1000 yd bench rest in mind. But nothing preventing placing targets at shorter ranges. Each location provides quite different wind conditions. No rooms just a shelter roof from sun and rain.

Two of his benches are made from granite about 4" thick. They are the most vibration free and solid benches I have ever shot from. You might want to consider this material as an option to concrete considering the effort ging into this project.

Andy.

I read this thread with interest. A friend in outback Oz who owns a ranch has built three bench set ups on the property primarily with 1000 yd bench rest in mind. But nothing preventing placing targets at shorter ranges. Each location provides quite different wind conditions. No rooms just a shelter roof from sun and rain.

Two of his benches are made from granite about 4" thick. They are the most vibration free and solid benches I have ever shot from. You might want to consider this material as an option to concrete considering the effort ging into this project.

Andy.

Something came to me last night while sleeping or trying to sleep. I would like to pour a concrete slab or table the entire length of the west wall or bench side wall. I need to benches and i would like to have a shelf in between the two benches for load work. What if i could make this one solid piece? I would have to pour it into place as i would never be able to pick it up and set it into place. There will be lots of braces and it will take a little time, but i think i may be able to pull it off. Unless something else comes to mind, i think this will be the plan. Lee

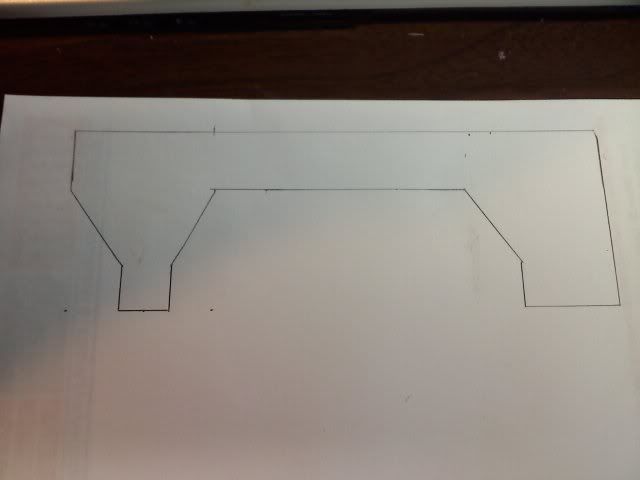

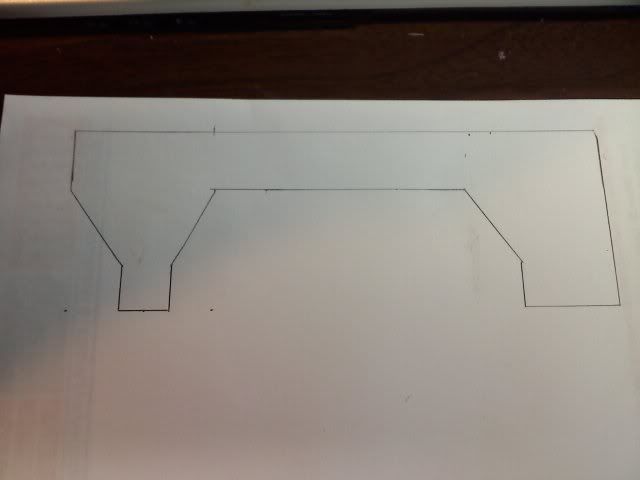

Maybe something like this? I dont draw all that well. I am a more of a "dive into it" type of fella, but this is a general idea. What do you think? Lee

my bench will be the right side bench as i am right handed and always will be. The left bench can be used for both, right and left handed shooters. I want the extra room on my bench to catch ejected brass and to have a place to clean rifles or whatever. I think with some .500" plywood and a 4x4 post across the front bolted to the wall with some cinder blocks in the back this is doable. I can spread the weight of the concrete out with some steel reinforcement rod. I think i am on to something here!! One other thing need to think about that i haven't yet is that the machine shop room is directly or will be directly to the south of this shoot room. I chose to have only one door to access this shoot room from the outside so no one could enter the room without knowing what is going on. I dont want someone to get stung with a rifle shot. this shouldn't ever be a problem anyway, so i am wondering if i should put an internal door from the shoot room to the machine shop room? I am really just thinking out loud here, but i am always open to suggestions. Gotta go, time to shoot a match this morning. I have been up since 4AM thinking about this room and bench. LOL!!! Hava a good day fellas! Lee

my bench will be the right side bench as i am right handed and always will be. The left bench can be used for both, right and left handed shooters. I want the extra room on my bench to catch ejected brass and to have a place to clean rifles or whatever. I think with some .500" plywood and a 4x4 post across the front bolted to the wall with some cinder blocks in the back this is doable. I can spread the weight of the concrete out with some steel reinforcement rod. I think i am on to something here!! One other thing need to think about that i haven't yet is that the machine shop room is directly or will be directly to the south of this shoot room. I chose to have only one door to access this shoot room from the outside so no one could enter the room without knowing what is going on. I dont want someone to get stung with a rifle shot. this shouldn't ever be a problem anyway, so i am wondering if i should put an internal door from the shoot room to the machine shop room? I am really just thinking out loud here, but i am always open to suggestions. Gotta go, time to shoot a match this morning. I have been up since 4AM thinking about this room and bench. LOL!!! Hava a good day fellas! Lee

Last edited:

Well, that's a small one........but I daresay the design is workable

http://www.sierraconcretefoundations.com/gallery.php?cat=Concrete_Tables&popmethod=

LOL

al

http://www.sierraconcretefoundations.com/gallery.php?cat=Concrete_Tables&popmethod=

LOL

al

BTW Skeet, I'm a liddle anal so on two of the benches I've poured I've isolated the legs from the slab (you'll see it referenced in the gallery if you look closely) but on the others I've just poured everything touching or even monolithically. The monolithic pours were for freestanding units.

So far, of 6 tables, the smallest of which is 25,000lb, none of them wiggle under foot traffic.

My main shooting bench, right outside my gunroom, is framed of wood setting on the slab floor. It's plenty solid but a big guy standing directly behind the shooter and stamping his feet hard can make the crosshairs wiggle. This is on a good base, the slab was poured over a subgrade that had been rolled in with a 100" vibratory highway roller.

al

So far, of 6 tables, the smallest of which is 25,000lb, none of them wiggle under foot traffic.

My main shooting bench, right outside my gunroom, is framed of wood setting on the slab floor. It's plenty solid but a big guy standing directly behind the shooter and stamping his feet hard can make the crosshairs wiggle. This is on a good base, the slab was poured over a subgrade that had been rolled in with a 100" vibratory highway roller.

al

No shooting for me this weekend. Had work to do on the range and i had a lot of fun doing so. I finished the sheeting, and got 95% of the trim done. The room is finally starting to look like something. Enjoy, and please post any suggestions you might have. With a little luck, i will start bench construction this week. Lee

One major mistake that i did make was with the outlets on the back wall. I should have set them at 4' this is going to cause some pretty major complications for me, as far as getting a proper bench built. I had an old piece of counter top that i set up in the corner, but i am not so sure thats a good spot for it. We will just have to see.

I am still thinking about building the bench as one solid piece across the front of the room. I dont want the bench to have any contact with the front wall, yet i need it as close to the wall as possible. I need to figure out a way that i can drop the 1by out after the concrete sets. I think i can do it! I can build a block wall across the front for support and pour the top block right into the pad itself a little. Three legs across the back and some steel reinforcement and i think it will work. Lots of bracing and short 2x4 stubs to support the wet concrete. Like i say, i just need to make were the ply wood bottom drops out from under the bench when set along with that front piece/ form.

One major mistake that i did make was with the outlets on the back wall. I should have set them at 4' this is going to cause some pretty major complications for me, as far as getting a proper bench built. I had an old piece of counter top that i set up in the corner, but i am not so sure thats a good spot for it. We will just have to see.

I am still thinking about building the bench as one solid piece across the front of the room. I dont want the bench to have any contact with the front wall, yet i need it as close to the wall as possible. I need to figure out a way that i can drop the 1by out after the concrete sets. I think i can do it! I can build a block wall across the front for support and pour the top block right into the pad itself a little. Three legs across the back and some steel reinforcement and i think it will work. Lots of bracing and short 2x4 stubs to support the wet concrete. Like i say, i just need to make were the ply wood bottom drops out from under the bench when set along with that front piece/ form.

Last edited: