S

sagreen83

Guest

Great progress last night. Got a few more parts on the stand, the lathe leveled and powered up and spinning. I'm pretty surprised at how quite this thing is. I need to get some thin foam to put between some of the flat metal covers and the stands cause they are rattling when the spindle is running. Anyone have any other ideas on how to quiet these sheet metal to sheet metal points?

I ran it forward and reverse at the lowest speed for 10 minutes. I read somewhere that other people are breaking in in each gear. Can someone tell me what the best way to break in the lathe is?

Also, notice this thing has a foot break. Its kind of a pain to install, but works best if you put it on before you bolt the lathe to the stand. It has a big spring that keeps it in the up position until you press it. That spring is next to impossible to install. The area is too tight to put any tools on the spring, and you cant get enough leverage to pull it into place. Took me about 2 hours but I figured out an easy way to put it on. Kinda backyard engineering, but worked great. Heres how.

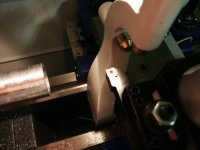

1) Reference attached picture Spring Install 1

2) Remove side access panel on stand under headstock.

3) Form a loop in the end of a piece of wire. I used electric fence wire.

4) Thread the wire under the stand, behind the foot break bar, and up and over the end of the spring.

5) I placed a hammer undernieth the stand to give the wire a smooth surface to pull against. I broke a bunch of wires first because the stand is sharp and when you pull the wire it breaks where it meets the stand.

6) Cut the wire about 2 foot outside the stand.

7) Wrap and loop the wire around a pipe or wrench. This is what you are going to pull with.

8) Move the footbreak to the up position.

9) Pull the pipe or wrench to extend the spring. I pulled it so that it extended just past the point on the footbreak where it connects.

10) If you have the spring mounted so that the opening in the end of the spring is facing you, you can jocky the spring while you are pulling it so that the footbreak will catch the end of the spring where it connects. Takes a couple of times to get it.

11) Drop the footbreak so that it catches the spring.

12) Cut and remove the wire.

I wouldnt put my hand in there while you are doing this. If that wire breaks its going to hurt real bad!

I ran it forward and reverse at the lowest speed for 10 minutes. I read somewhere that other people are breaking in in each gear. Can someone tell me what the best way to break in the lathe is?

Also, notice this thing has a foot break. Its kind of a pain to install, but works best if you put it on before you bolt the lathe to the stand. It has a big spring that keeps it in the up position until you press it. That spring is next to impossible to install. The area is too tight to put any tools on the spring, and you cant get enough leverage to pull it into place. Took me about 2 hours but I figured out an easy way to put it on. Kinda backyard engineering, but worked great. Heres how.

1) Reference attached picture Spring Install 1

2) Remove side access panel on stand under headstock.

3) Form a loop in the end of a piece of wire. I used electric fence wire.

4) Thread the wire under the stand, behind the foot break bar, and up and over the end of the spring.

5) I placed a hammer undernieth the stand to give the wire a smooth surface to pull against. I broke a bunch of wires first because the stand is sharp and when you pull the wire it breaks where it meets the stand.

6) Cut the wire about 2 foot outside the stand.

7) Wrap and loop the wire around a pipe or wrench. This is what you are going to pull with.

8) Move the footbreak to the up position.

9) Pull the pipe or wrench to extend the spring. I pulled it so that it extended just past the point on the footbreak where it connects.

10) If you have the spring mounted so that the opening in the end of the spring is facing you, you can jocky the spring while you are pulling it so that the footbreak will catch the end of the spring where it connects. Takes a couple of times to get it.

11) Drop the footbreak so that it catches the spring.

12) Cut and remove the wire.

I wouldnt put my hand in there while you are doing this. If that wire breaks its going to hurt real bad!