J

jmcasto

Guest

Greetings. I am a long-time reloader but relatively new to the level of detail with respect to measuring the shoulders on brass. I'm confused by what I'm seeing and I'd appreciate any thoughts and advice you might have.

Last week I prepped some new .222 Lapua brass, to include turning necks, cleaning up primer pockets and full-length resizing with an RCBS Bench Rest die. I used a Whidden Case Guage (a lovely tool) to set the sizing die up. I seated the bullets to touch the lands of my rifle (using a Hornady Length Guage) and took them to the range. Everything went fine at the range and I was pleased with the accuracy, despite firing and fire forming of new cases.

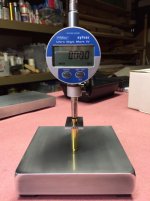

Today I was measuring the shoulders on the cases in preperation for reloading and was surprised to find a + or - .008 headspace in the brass. I used both the Whidden Guage and my Fowler-Sylvac indicator (see picture below) and measured the cases several times to get consistent readings. I'm pretty confident the measurements are correct. I also measured the concentricity of the shoulders at the approximate "headspace datum" and the cases vary by no more than .0005, so I don't think case concentricity is contributing to the case length variation. My questions are: (1) Why such a large variation in cases fired in the same rifle? (2) Most importantly, considering the .008 variance, how do I set up my sizing die to get the often-recommended .001 shoulder bump? (3). What the heck am I missing or not understanding?

Best regards,

Joel

Last week I prepped some new .222 Lapua brass, to include turning necks, cleaning up primer pockets and full-length resizing with an RCBS Bench Rest die. I used a Whidden Case Guage (a lovely tool) to set the sizing die up. I seated the bullets to touch the lands of my rifle (using a Hornady Length Guage) and took them to the range. Everything went fine at the range and I was pleased with the accuracy, despite firing and fire forming of new cases.

Today I was measuring the shoulders on the cases in preperation for reloading and was surprised to find a + or - .008 headspace in the brass. I used both the Whidden Guage and my Fowler-Sylvac indicator (see picture below) and measured the cases several times to get consistent readings. I'm pretty confident the measurements are correct. I also measured the concentricity of the shoulders at the approximate "headspace datum" and the cases vary by no more than .0005, so I don't think case concentricity is contributing to the case length variation. My questions are: (1) Why such a large variation in cases fired in the same rifle? (2) Most importantly, considering the .008 variance, how do I set up my sizing die to get the often-recommended .001 shoulder bump? (3). What the heck am I missing or not understanding?

Best regards,

Joel