Jay Cutright

New member

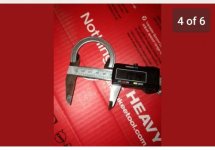

Anyone know where to get a good quality Thrust bearing to replace the felt washer?

I was bidding on one on eBay and got outbid.

I'm going to take the felt washer into a bearing shop and see what they come up with. I thought a post here might generate a part number.

I was bidding on one on eBay and got outbid.

I'm going to take the felt washer into a bearing shop and see what they come up with. I thought a post here might generate a part number.