Boyd Allen

Active member

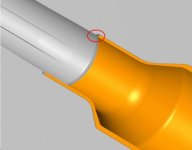

In the thread about bullets' pressure rings, there was some discussion of freebore and groove diameters. Has anyone considered that having a more gradual transition between chamber neck diameter and the freebore would have any advantage....or disadvantage?