Boyd Allen

Active member

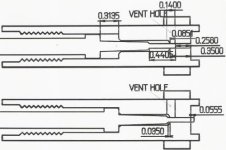

A friend has a custom barreled .204 Ruger on a Remington 700 action, It is a single shot with a heavily modified pillar bedded stock. Although the rifle did well as a .222 (custom barrel, tight neck chamber), it was about to drive him to distraction trying to get the .204 to shoot. One thing that became evident was that there was a difference in the pressures that he had loaded the .222 to as compared to what he has been trying for in performance with the .204. It seemed that the only loads that would group reliably were at a lower than desired velocity. Another new problem that came along with the higher pressures was extreme cratering that looked like a short tube, evidence of excessive pin tip clearance in the bolt face. I told him that Greg Tannel of Gre-Tan Rifles would do an excellent job of fixing that problem by bushing the pin tip, reducing the tip size, and turning the tip long enough to work with a tip hole that contained the tip throughout the entire firing cycle (which the Remington does not). Eventually, he sent off the bolt, and is very pleased with the work, and the price ($60). His craters are gone, and his rifle is shooting very well, much better. There is some question as to why, because he just switched to VV140, but I remember his previous results with a variety of powders and I am poretty sure that having the firing pin tip properly guided is largely responsible. Perhaps I can persuade him to revisit some previous powders loaded to the same 3,900 fps with 39 gr. Blitzkings that is doing so well (5 shots 3/8") for him with the 140. Greg told me that the reason that he makes the bushings as long as he does is that he had traced a problem with fliers to the pin being in stock configuration, and the problem went away with the tip in a long enough bushing to guide it full stroke.