E

Exitpupil

Guest

I do a lot of airgun and some limited rimfire work and frequently use barrels too short to go thru my headstock, even with the rear spindle tube drilled and tapped as a spider. I have considered trying to make some sort of thin chuck to gain a couple inches at the headstock. What are folks doing on chambering barrels in the 14" - 19" range?

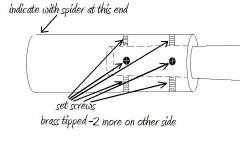

I spent about 50 hours with a long homemade boring bar truing up the spindle tube then honing it. I currently use one of two centering methods. One is to turn targets on the barrel concentric to the bore and make a custom fit puck to slide into the spindle tube to hold the barrel. I also have a precision fit rod with interchangable centers to slide into the spindle tube. Both methods allow no way to indicate or verify the muzzle position inside the tube and of course these parts have to have some clearance to operate. My lathe is a Jet 14x40 about 10 years old. Thanks, Will Piatt

I spent about 50 hours with a long homemade boring bar truing up the spindle tube then honing it. I currently use one of two centering methods. One is to turn targets on the barrel concentric to the bore and make a custom fit puck to slide into the spindle tube to hold the barrel. I also have a precision fit rod with interchangable centers to slide into the spindle tube. Both methods allow no way to indicate or verify the muzzle position inside the tube and of course these parts have to have some clearance to operate. My lathe is a Jet 14x40 about 10 years old. Thanks, Will Piatt