The key words are "competent Gunsmith".

Most modern actions are very close in their tolerances. Bats, Pandas, Stillers, and a few others have set dimensions that a Gunsmith can adhere to that allows a shooter to interchange barrels with no worry.

Changing a barrel on a Benchrest Rifle is really just an exercise in common sense. First, you have have a barrel vice that will hold he barrel secure so as to loosen and tighten the barrel. You then have to have a proper action wrench for that action.

Secure the barrel in the barrel vice, insert the action wrench properly, and turn counterclockwise until it breaks free. Once it so loose, loosen the barrel vice and screw the barrel out by hand.

Take the new barrel, and make sure the threads and face are clean. Apply a thin coat of what ever anti-seize compound you like to the threads and to the face. Hold the rifle verticle, and gently insert the barrel into the threads, making sure it is going in straight. Screw the new barrel in by hand until it contacts the shoulder. A note: if at anytime it stops, or gets tight, STOP. Something is amiss. Nothing is worse than galling a Stainless Steel Barrel in a Stainless Steel Action.

Put the barrel in the barrel vice and secure it. I like to use a piece of note pad paper to add friction. Insert the action wrench and tighten.

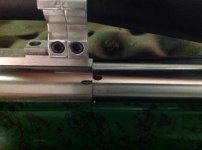

Now, here is the part where many disagree. How tight is tight enough. What I like to do is seat the barrel firmly against the action face, and then, with a sharpie pen, make a mark from the barrel to the action. Then, I tighten the barrel until these two marks are about 3/32 to 1/8 inch separating them. That will probably take about 75/80 ft pounds of torque, depending on the action. The attached picture shows this.

Nothing is worse than NOT getting the barrel tight enough. I have cured more than one shooter's ill shooting rifle by doing nothing more than tightening the barrel. Years ago, somebody made the statement that all you had to do was snap the barrel against the action face by hand and it would be tight enough. Who ever said this probably was hoping everybody he was shooting against would follow his advice.

http://benchrest.com/attachment.php?attachmentid=15850&stc=1&d=1422931842