Gents,

I was messing with a Remington 700 trigger (Walker style) yesterday, and like others I had worked on, this one was temperamental, i.e., weight of pull varied quite a bit (6-8 oz's) when set at my desired weight, in this case 3 pounds. What was weird, though, was their were other weight of pulls that were very consistent, specifically 1 lbs, 15 oz's. The confounded thing broke at 1.14-1.15 every time, which is too light for the rifles application. It was also consistent at about 4 pounds.

To make matters even more confusing, this particular trigger was timed half-way decently in that the sear didn't contact the trigger connector until the bolt was cammed into battery. I think every 700 trigger I'd looked at previously had these two surfaces getting bashed into one another when the bolt was pushed forward. Sear hand-off on this one was about .054. A bit too much, but a helluva lot better than most factory 700 triggers.

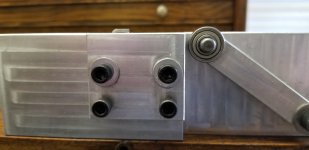

The trigger got my typical treatment, in that the engaging surfaces were polished up to a black Arkansas stone in a fixture I made for the purpose, and then using the triggers adjustment screws to dial it in from there. 783 different pull-weight springs have been tried. The trigger connector got a wee bit of negative engagement stoned into it a'la W. Hambly-Clark's tutorials and will hold at cock with the trigger spring removed. It will pass the typical trigger safety check.

I SUSPECT that the tolerances built into the trigger have something to do with the inconsistency...I'm thinking they're allowing the engaging surfaces to contact each other differently from cycle to cycle. I thought about making some washer shims out of delrin to take out some of the wobblies in the sear/safety cam and trigger as they sit on their respective pins, but that may introduce some unwanted friction and make matters worse. Glueing the trigger connector to the trigger is another thought, as is dialing in the sear hand-off.

While I'm not the second coming of Arnold Jewell, I was trained by a former Remington warranty armorer on 700 triggers, have read W. Hambly-Clark's book wherein he writes at length about tuning-up 700 triggers, and spent some time talking to Dan (Dans40x) about trigger timing, so it's not like this is my first trigger rodeo...

So...what say you guys? Have you experienced anything similar whilst tuning 700 triggers, and if so, what did you do to combat these issues?

Thanks,

Justin

I was messing with a Remington 700 trigger (Walker style) yesterday, and like others I had worked on, this one was temperamental, i.e., weight of pull varied quite a bit (6-8 oz's) when set at my desired weight, in this case 3 pounds. What was weird, though, was their were other weight of pulls that were very consistent, specifically 1 lbs, 15 oz's. The confounded thing broke at 1.14-1.15 every time, which is too light for the rifles application. It was also consistent at about 4 pounds.

To make matters even more confusing, this particular trigger was timed half-way decently in that the sear didn't contact the trigger connector until the bolt was cammed into battery. I think every 700 trigger I'd looked at previously had these two surfaces getting bashed into one another when the bolt was pushed forward. Sear hand-off on this one was about .054. A bit too much, but a helluva lot better than most factory 700 triggers.

The trigger got my typical treatment, in that the engaging surfaces were polished up to a black Arkansas stone in a fixture I made for the purpose, and then using the triggers adjustment screws to dial it in from there. 783 different pull-weight springs have been tried. The trigger connector got a wee bit of negative engagement stoned into it a'la W. Hambly-Clark's tutorials and will hold at cock with the trigger spring removed. It will pass the typical trigger safety check.

I SUSPECT that the tolerances built into the trigger have something to do with the inconsistency...I'm thinking they're allowing the engaging surfaces to contact each other differently from cycle to cycle. I thought about making some washer shims out of delrin to take out some of the wobblies in the sear/safety cam and trigger as they sit on their respective pins, but that may introduce some unwanted friction and make matters worse. Glueing the trigger connector to the trigger is another thought, as is dialing in the sear hand-off.

While I'm not the second coming of Arnold Jewell, I was trained by a former Remington warranty armorer on 700 triggers, have read W. Hambly-Clark's book wherein he writes at length about tuning-up 700 triggers, and spent some time talking to Dan (Dans40x) about trigger timing, so it's not like this is my first trigger rodeo...

So...what say you guys? Have you experienced anything similar whilst tuning 700 triggers, and if so, what did you do to combat these issues?

Thanks,

Justin

Last edited: