adamsgt

Jerry Adams

The original thread was getting long so I thought I'd start afresh at a further point in the exploration of the problem. Went to my shop today to check some things on the lathe. Pulling on the tool post revealed more than a little movement. Adjusted the gib and got it out. The compound was just fine. So I proceeded to try to cut some threads. This time I put some dykem on the metal to view each cut. Now before I go into that I'm going to post a picture of the bolt jeweling fixture adjustment screw that I made in gunsmithing class. I have cut decent threads in the past.

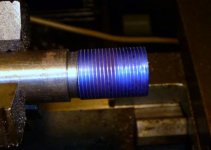

The next picture is the first pass for 16 tpi

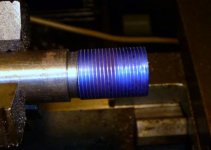

The next two pictures are after two more passes

This last picture cleaned up show three distinct tracks for the three passes. I engaged the half nuts on the same number. I'm stumped as to what is causing this. One way to eliminate the problem is to blow 5 grand on a new lathe. Or I can take my barrels, reamers and gages to someone with a working lathe. Stick comes to mind except I lost the url to his website. Lew chime in if you read this. That would be cheaper than buying a new lathe. I hope somebody out there has some idea of what I might try next.

The next picture is the first pass for 16 tpi

The next two pictures are after two more passes

This last picture cleaned up show three distinct tracks for the three passes. I engaged the half nuts on the same number. I'm stumped as to what is causing this. One way to eliminate the problem is to blow 5 grand on a new lathe. Or I can take my barrels, reamers and gages to someone with a working lathe. Stick comes to mind except I lost the url to his website. Lew chime in if you read this. That would be cheaper than buying a new lathe. I hope somebody out there has some idea of what I might try next.