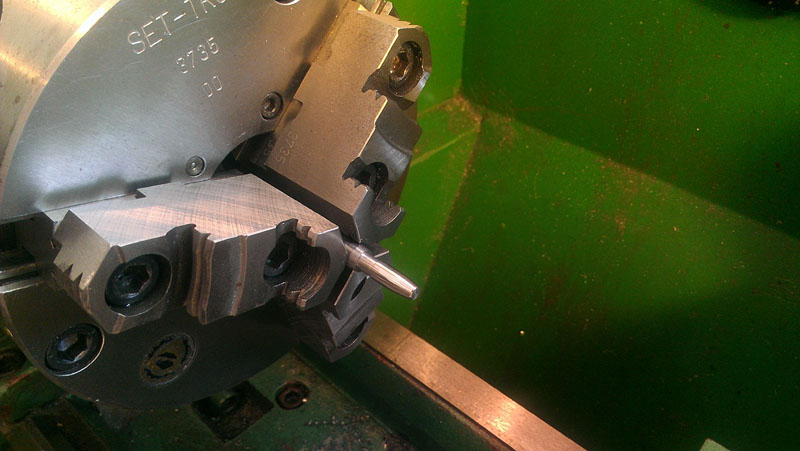

This is my first time I hardened and tempered anything and it all came out pretty darn nice and VERY easy to do. I needed a larger mandrel that was a few tenths bigger than what I had. I started with 5/16 oil hardening drill rod. Did all the machine work and polished the finished sized area. Took my propane torch with a "tornado" head on it using MAPP gas and heated the mandrel till it was no longer magnetic. Dipped it in a cup of oil to cool and then tempered at 400 degrees for an hour in a toaster oven. Out came out a cool looking hardened part. Now, have to try and see how well it works...