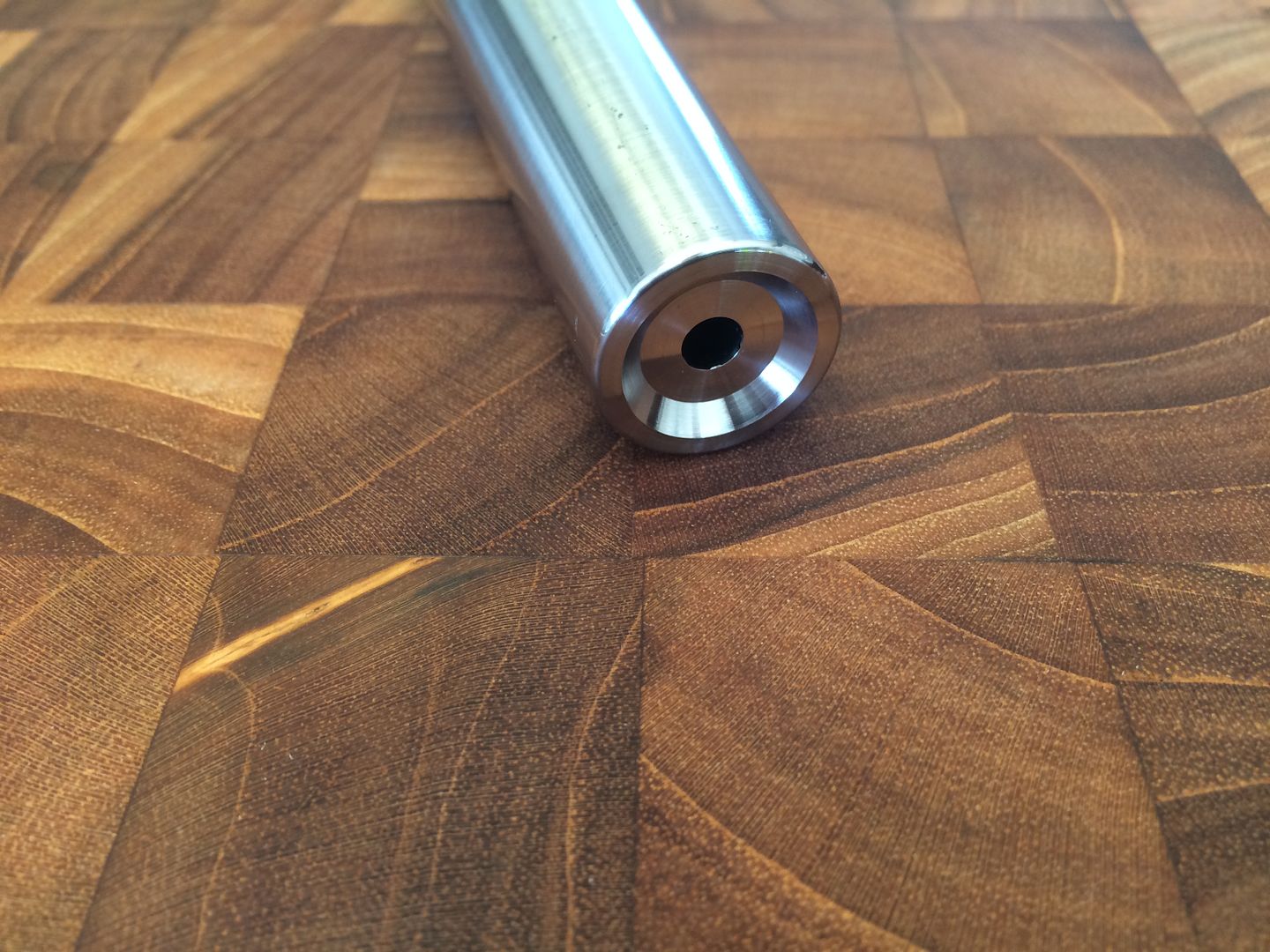

Can anyone tell me the origin of this and if there is any really significance to the 11 degree angle that a target crown is typically cut to?

I guess we could crown a muzzle anywhere from square in over. Im not really convinced that pushing the crown in by 11 degrees plays much of a part in protecting the crown so why exactly do we do it?

Ive seen some guys cut a mini 45 degree crown after the initial 11 degree face and they say they get just as goo a result. Ive only ever done 11 degree ones but is there only one way to skin this cat?

I guess we could crown a muzzle anywhere from square in over. Im not really convinced that pushing the crown in by 11 degrees plays much of a part in protecting the crown so why exactly do we do it?

Ive seen some guys cut a mini 45 degree crown after the initial 11 degree face and they say they get just as goo a result. Ive only ever done 11 degree ones but is there only one way to skin this cat?

Last edited: